Dissolved Nitrogen Flotation

Explosion Proof Wastewater Treatment for Oil & Gas Industry

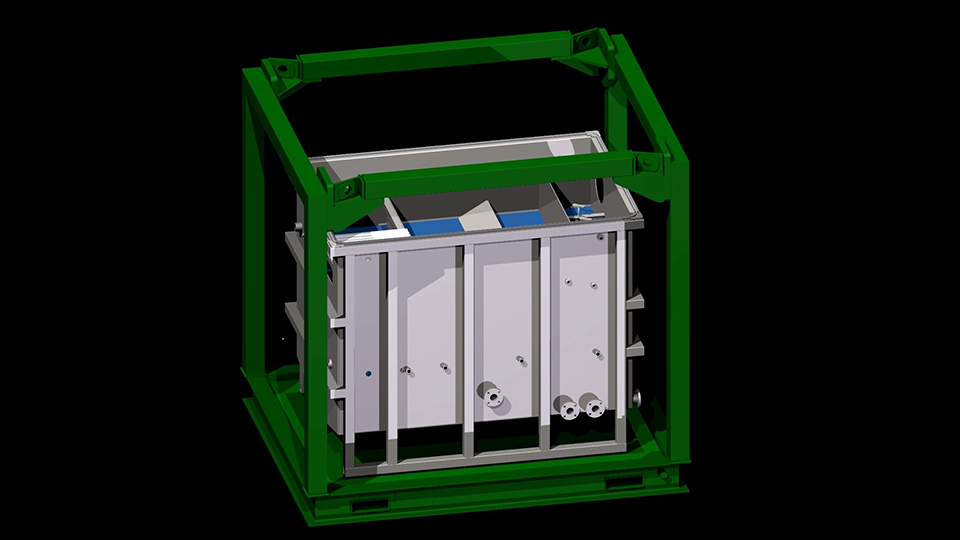

Replace slow and less effective Dissolved Gas Flotation (DGF’s) for oil & gas wastewater treatment with the explosion-proof Dissolved Nitrogen Flotation (DNF) system from Ground Effects Environmental Services (GEE). The GEE DNF uses nitrogen to eliminate the risk of an explosion, while being a highly efficient pre-treatment step for the separation of suspended solids and oil and grease contaminants from wastewater. The compact GEE DNF system has high removal rates, 99.9% runtime and a robust design. It is extremely effective as a post-EOX step. The DNF can either be integrated in a complete solution or offered as a single product for your wastewater treatment.

Sectors

Problems Solved

The Science Behind the Dissolved Nitrogen Flotation (DNF) System

GEE’s Dissolved Nitrogen Flotation (DNF) System replaces air with nitrogen to completely remove the potential of an explosion. The system then acts like a regular dissolved flotation process by forcing oil particles to coalesce then float to the surface where they are skimmed and remediated. It is more effective than the Dissolved Gas Flotation (DGFs) currently in use in the oil & gas industry. Use of the GEE DNF increases particle separation for more effective removal rates and safety.

Benefits

Explosion Proof

By replacing air with nitrogen the risk of explosion is eliminated.

High Removal Effiencies

The GEE DNF is more effiencient than competing Dissolved Gas Flotation (DGF) and Induced Gas Flotation (IGF). The DNF uses a chain skimmer system simliar to a DAF but operates under a nitrogen blanket to eliminate risk of explosion.

CSA, UL and IECEx Approved

We design and build to all North American and international standards, including CSA, UL, IECEx approved if needed.