Wastewater Treatment & Ultrafines Removal from OBM for Oil & Gas

Whether it’s for on site wastewater treatment for re-use or ultrafines removal from Oil Based Mud (OBM), Ground Effects Environmental Services (GEE) is a world-leader in electrokinetic systems for cost effective onsite wastewater treatment and ultrafines removal – onshore or offshore.

Gain huge savings treating wastewater for re-use with our turnkey, high-flow Electrocatalytic Oxidation (EOX) system. The EOX is a chemical-free approach to solving your wastewater problems. Low maintenance, low consumables and high runtimes add up to one thing—a great bottom line.

Our innovative Electro Separation Cell (ESC) removes ultrafines from synthetic and OBM without chemicals or heat and can be manufactured for onshore or offshore use. Low maintenance and easy to use, the ESC will save you thousands of dollars a day by treating your Synthetic OBM or OBM onsite and reclaiming drilling fluid for re-use.

Proven Technology

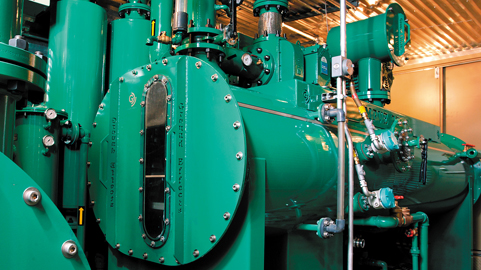

GEE is a world leader in using advanced electrocatalytic oxidation to treat wastewater. Fast, chemical-free wastewater treatment, the patented EOX treatment technology combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalytic oxidation approach in the world.

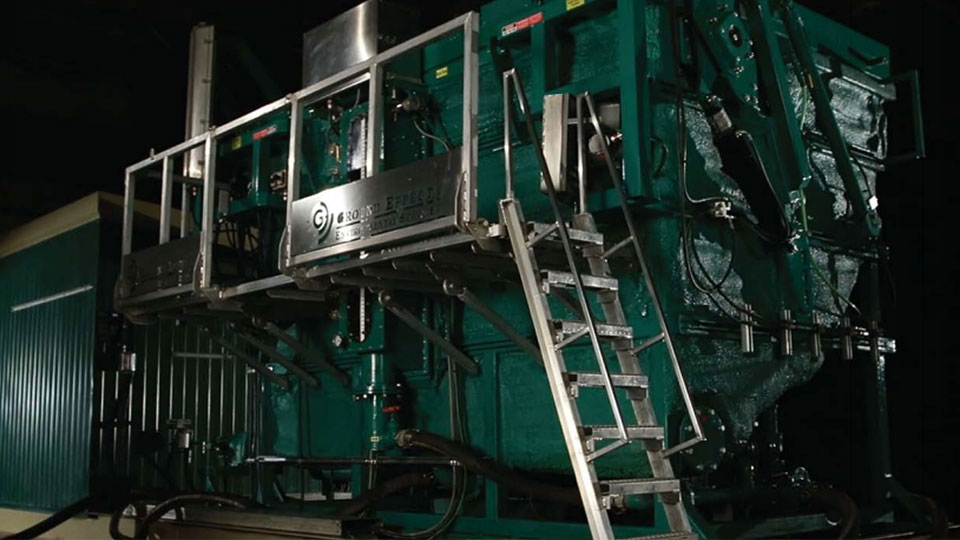

Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals. It is fast, compact and effective.

A GEE-patented technology, the Electro Separation Cell (ESC) system is a chemical-free, turnkey OBM and drilling fluid recovery system for the oil and gas industry. The ESC consistently removes Low Gravity Solids (LGS) from Synthetic and Oil-Based Mud (OBM) using in a flow-through mode on a rig or batch mode for pure oil recovery from spent mud.

The Proof

Compact footprint. Huge savings. Low maintenance.

We build our EOX to be a turnkey technology that is as efficient as it is compact. With high flow rates and high runtimes, the EOX makes and saves you money. In addition, the EOX is scalable to any flow rate required and can be optimized or monitored from anywhere in the world through our mobile app for Apple or Android.

About Ground Effects

Since 1998, Ground Effects Environmental Services (GEE) leads the way by offering the most effective and innovative electrokinetic innovations in the world for the oil and gas industry for wastewater treatment or solids control treatment of OBM. Based in Regina, Saskatchewan, Canada, GEE is an innovator of wastewater and liquids / solids separation technology for the oil & gas, mining, municipal, agriculture, food and industrial sectors.

Read about our ESG practices here.EOX Features

Related Products

EOX - Electrocatalytic Oxidation System

Powerful, Chemical-Free Wastewater Treatment

A GEE-patented technology, the Electrocatalytic Oxidation (EOX) treatment system is a chemical-free, turnkey wastewater treatment process for oil and gas, municipal, industrial and agricultural industries. The EOX combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalyitic oxidation approach found anywhere. Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals.

ESC - Electro Separation Cell System

Ultrafine Colloidal Solids Control for OBM

The ESC is the only process in the world that can remove colloidal solids consistently from Synthetic and Oil-Based Mud. With the ESC system you can program the desired density output on the human machine interface to your exact customer density specifications. The result is exactly what you require, which results in huge savings.

EK3 - Electrokinetic Remediation System

Cost-Effective Eectrokinetic Remediation for Low Permeability Soils

The GEE EK3 Electrokinetic Remediation System is a proprietary in situ remediation system for salts, metals, hydrocarbons and chlorinated hydrocarbons in soil and ground water. A GEE-patented technology, the EK3 is an extremely effective and proven alternative to the ‘dig and dump’ approach to groundwater and soil contamination.

MPE - Multi-Phase Extraction

Multi-Phase Extraction (MPE): Insitu Remediation with 99.9% Runtime

At every step, our team focuses on making our equipment powerful, versatile and easy to maintain. Our insitu remediation Multi-Phase Extractor 2700 Series is another example of our innovative design in action. Our integrated treatment system incorporates an oil/water separator and vacuum air stripper in one system, reducing maintenance. This extremely quiet unit makes it ideal for operation in residential areas.