Ground Effects Products

Electrocatalytic Oxidation System

Powerful, Chemical-Free Wastewater Treatment

A GEE-patented technology, the Electrocatalytic Oxidation (EOX) treatment system is a chemical-free, turnkey wastewater treatment process for oil and gas, municipal, industrial and agricultural industries. The EOX combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalyitic oxidation approach found anywhere. Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals.

Electro Separation Cell System

Ultrafine Colloidal Solids Control for OBM

The ESC is the only process in the world that can remove colloidal solids consistently from Synthetic and Oil-Based Mud. With the ESC system you can program the desired density output on the human machine interface to your exact customer density specifications. The result is exactly what you require, which results in huge savings.

DAF - Dissolved Air Flotation

Dissolved Air Flotation (DAF) System

GEE’s Dissolved Air Flotation (DAF) system is a highly efficient treatment for the separation of suspended solids and oil and grease contaminants from wastewater. The compact GEE DAF system boasts high removal rates, 99.9% runtime and a robust design. The compact DAF can either be integrated in a complete solution or offered as a single product for your wastewater treatment.

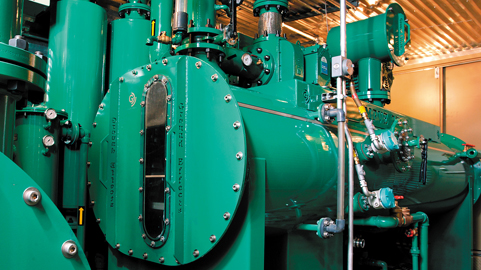

AOR - Advanced Oxidation Reactor

Advanced Oxidation Wastewater Treatment

The Advanced Oxidation Reactor from GEE is unlike any ozone reactor on the planet. The proprietary design with high pressure, high agitation and microbubbles results in low high efficiency, high destruction of contaminants and low residence time.

Filtration - Filtration Carbon/Media

Media Filtration

Ground Effects Environmental Services Inc. offers a wide range of media filters in various types and sizes, available for both rental and purchase. These versatile filtration systems are designed for multiple applications, effectively removing contaminants from waste streams. Media filtration utilizes different materials (the "media") to capture suspended solids and particles, providing reliable treatment solutions for liquids and gases.

Silica Carbide Flat Sheet Ceramic Membrane

Durable, MF/UF Filtration Range, Chemically Inert

Ground Effects combines our patented EOX Electrocatalytic oxidation technology with flat plate ceramic membranes to make the most advanced industrial waste water treatment processes on the planet.

DNF - Dissolved Nitrogen Flotation

Explosion Proof Flotation Separation for Oil & Gas Industry

Replace slow and less effective Dissolved Gas Flotation (DGF’s) for oil & gas wastewater treatment with the explosion-proof Dissolved Nitrogen Flotation (DNF) system. The GEE DNF uses nitrogen to completely eliminate the possibility of an explosion, while being a highly efficient pre-treatment step for the separation of suspended solids and oil and grease contaminants from wastewater.

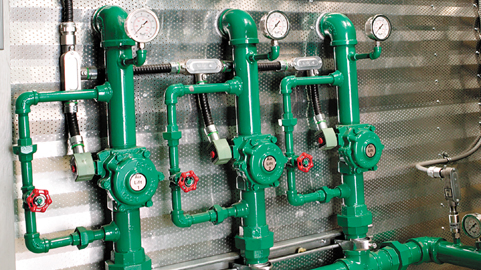

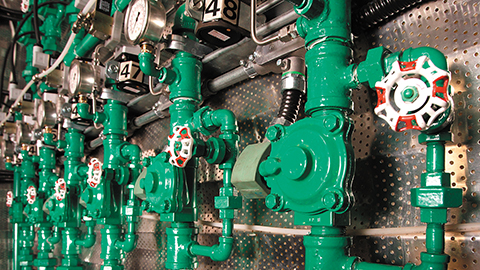

MPE - Multi-Phase Extraction

Multi-Phase Extraction (MPE): Insitu Remediation with 99.9% Runtime

At every step, our team focuses on making our equipment powerful, versatile and easy to maintain. Our insitu remediation Multi-Phase Extractor 2700 Series is another example of our innovative design in action. Our integrated treatment system incorporates an oil/water separator and vacuum air stripper in one system, reducing maintenance. This extremely quiet unit makes it ideal for operation in residential areas.

EK3 - Electrokinetic Remediation System

Cost-Effective Eectrokinetic Remediation for Low Permeability Soils

The GEE EK3 Electrokinetic Remediation System is a proprietary in situ remediation system for salts, metals, hydrocarbons and chlorinated hydrocarbons in soil and ground water. A GEE-patented technology, the EK3 is an extremely effective and proven alternative to the ‘dig and dump’ approach to groundwater and soil contamination.

Oil Water Separator

High Efficiency Oil/Water (O/W) Separation System

GEE O/W Separators are built for high-efficiency, increased removal rates and low-maintenance. We know achieving optimum runtimes and lower costs is important to your project and we deliver. Plus, we use M-Pak coalescing media and/or Diffused Air Flotation (DAF) for maximum efficiency and easy clean out. An array of flow rates and sizes are available.

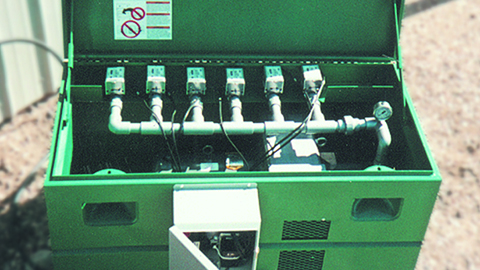

Nutrient Injection

Enhanced Biological Remediation: Nutrient Injection System

GEE’s Nutrient Injection System injects nutrients into soil formation to enhance microbial activity. The GEE approach accelerates the bio-degradation process in saturated and vadoze zones by supplying a nutrient source for indigenous microorganisms in hydrocarbon and nitrate sites. For nitrate sites, we inject a cocktail of bio-supplements into the soil formation to reduce nitrate contamination by increasing anaerobic bacterial populations.

SVE - Soil Vapour Extraction

Soil Vapour Extraction for VOCs: Smart In Situ Remediation

The GEE Soil Vapour Extraction (SVE) system is compact, economical and runs efficiently with low maintenance. The GEE SVE boasts a compact footprint and efficient design that provides enhanced vapour extraction with an operating value that benefits the bottom line.

Air Sparging

In Situ Air Sparging: Bio-Degradation of Groundwater Contaminants

The GEE Air Sparging system enhances bio-degradation of contaminants in and above groundwater by injecting air directly into groundwater and volatilizing the contaminants. Also known as in situ air stripping, the GEE Air Sparging system is an enhancement technology to the GEE Soil Vapour Extractor (SVE). The Air Sparging system is compact and quiet and can be custom-manufactured for your specific needs with a wide variety of flow rates and pressures available.

PALS - Pneumatic AirLift System

Cost-Effective Downhole Water-Lifting Tool

Exclusive innovation to GEE, the Pneumatic AirLift System (PALS) is an easy-to-use, cost-effective downhole fluid-lift system and remediation enhancing technology. When you add the PALS to your existing GEE equipment, what's good gets even better. The PALS keeps the wells free of silts and can lift fluids up to 150 feet. It helps develop well sites faster and it replaces expensive systems such as pneumatic and electric submersible pumps while achieving amazing results. Plus, PALS can be utilized in vertical or horizontal applications. When used in conjunction with the GEE MPE / Pneumatic Fracturing Systems (PFS), PALS increases efficiency significantly and is successful in dewatering wells up to 150 feet.

PFS - Pneumatic Fracturing System

A Multi-Phase Extraction (MPE) Enhancement Technology

Designed to pneumatically fracture tight soils such as clay, the GEE PFS causes fracturing by injecting air (or gases) at a pressure exceeding the natural strength and in situ stresses already in the formation, thus creating more pathways for our MPE system to use. The result is increased efficiency, reduced remediation time and reduced costs.

SANOZONE - SANOZONE Pathogen Bio-Decontamination

Chemical-Free Bio-Decontamination of Viruses and Bacteria

The SANOZONE system is a chemical-free, bio-decontamination unit to eradicate viruses, bacteria and other pathogens in response to the current COVID-19 pandemic. The SANOZONE kills pathogens on every surface in the decontamination zone, while providing peace of mind to staff, customers and business owners ensuring their space is sanitized daily to the highest possible level.