In Situ / on Site Wastewater & Remediation Systems for the Mining Sector

Eliminate the need for expensive approaches for on site wastewater treatment and soil remediation for the mining industry.

Ground Effects Environmental Services (GEE) is a world leader in mining in situ remediation. GEE can remediate a broad spectrum of contaminants from wastewater, soil and groundwater on site, cost-effectively and with high runtimes and compact footprints.

An industry leader in remediation since 1998, GEE has extensive experience in manufacturing and employing remediation technologies, including our mobile EOX technology for wastewater, Multi-Phase Extraction (MPE), Soil Vapour Extraction (SVE), Diffused Air Flotation (DAF), Horizontal Soil Heating, Pneumatic AirLift System (PALS), Pneumatic Fracturing System (PFS), Air Sparging, Nutrient Injection System / bioremediation and the GEE EK3 system for salt remediation. Both the EOX and the EK3 systems use advanced and proprietary electrokinetics to remediate in situ, cost-effectively and quickly.

Proven Systems and Proven Track Record

GEE has a proven track record cleaning up heavy metals and dense, non-aqueous phase liquids (DNAPLs) including VOCs such as perchloroethylene (PCE), polychlorinated biphenyls (PCB) and trichlorethylene (TCE). GEE’s technologies also clean heavy crude oil, as well as light non-aqueous phase liquids (LNAPLs) including petroleum hydrocarbons (PHCs). We are also one of the few companies in the world that can remediate salt from soil and groundwater in situ in a cost-effective and environmentally sustainable approach with our EK3 system.

GEE boasts two innovations for mining wastewater treatment:

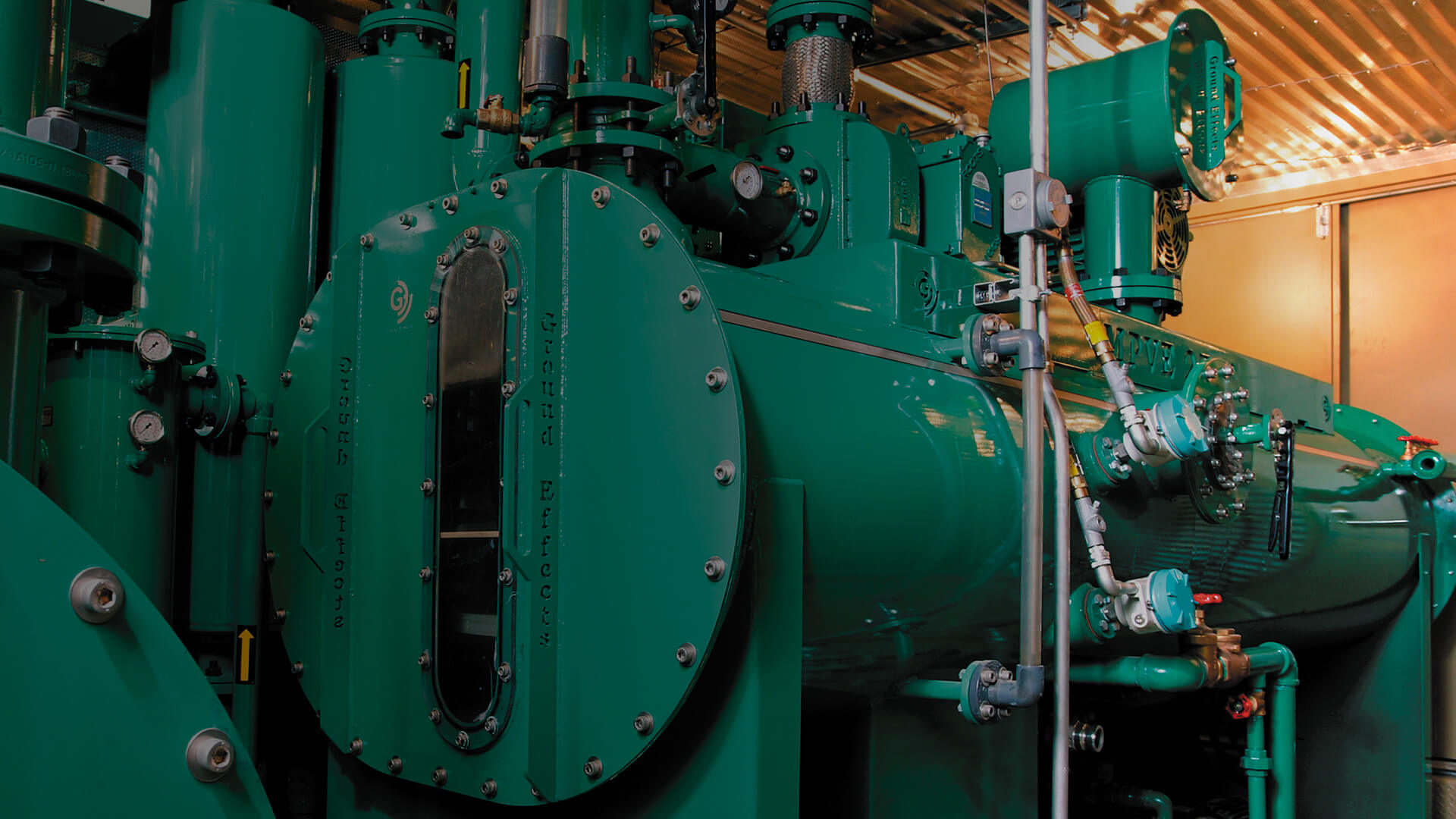

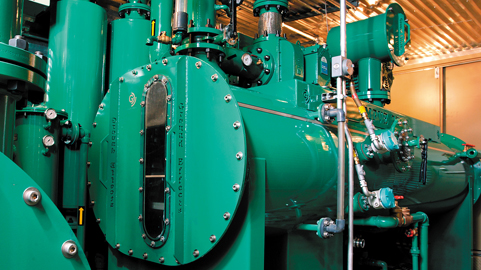

The EOX combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalyitic oxidation approach found anywhere. Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals.

GEE’s Dissolved Air Flotation (DAF) system is a highly efficient treatment for the separation of suspended solids and oil and grease contaminants from wastewater. The compact DAF can either be integrated in a complete solution or offered as a single product for your mining wastewater treatment.

GEE is a world leader in using innovative approaches and advanced electrokinetics to treat contaminated soil, groundwater and wastewater for VOCs, salt and metals. GEE has been remediating mining contaminants and treating wastewater for more than 20 years and has won numerous awards for our innovations.

The Proof

Compact footprint. Huge savings. Low maintenance.

We build our systems to be turnkey technologies that are as efficient as they are compact. With high flow rates and 99.9% runtimes, our technologies make and save you money. In addition, all of our in situ remediation technologies are scalable, easily integrated into current processes and can be fixed plant or mobile.

About Ground Effects

Ground Effects Environmental Services (GEE) offers the most effective in situ remediation treatment processes available in the world. Since 1998, we have been a dedicated technology manufacturer that provides specialized products for innovative and effective industrial remediation and wastewater treatment. Based in Regina, Saskatchewan, Canada, we are a world-leading environmental technology development company that specializes in electrokinetic technologies and providing exceptional results for the ever-changing needs of the mining, oil and gas, industrial, manufacturing, agriculture, food, and municipalities sectors.

Read about our ESG practices here.Features

Related Products

EOX - Electrocatalytic Oxidation System

Powerful, Chemical-Free Wastewater Treatment

A GEE-patented technology, the Electrocatalytic Oxidation (EOX) treatment system is a chemical-free, turnkey wastewater treatment process for oil and gas, municipal, industrial and agricultural industries. The EOX combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalyitic oxidation approach found anywhere. Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals.

DAF - Dissolved Air Flotation

Dissolved Air Flotation (DAF) System

GEE’s Dissolved Air Flotation (DAF) system is a highly efficient treatment for the separation of suspended solids and oil and grease contaminants from wastewater. The compact GEE DAF system boasts high removal rates, 99.9% runtime and a robust design. The compact DAF can either be integrated in a complete solution or offered as a single product for your wastewater treatment.

EK3 - Electrokinetic Remediation System

Cost-Effective Eectrokinetic Remediation for Low Permeability Soils

The GEE EK3 Electrokinetic Remediation System is a proprietary in situ remediation system for salts, metals, hydrocarbons and chlorinated hydrocarbons in soil and ground water. A GEE-patented technology, the EK3 is an extremely effective and proven alternative to the ‘dig and dump’ approach to groundwater and soil contamination.

MPE - Multi-Phase Extraction

Multi-Phase Extraction (MPE): Insitu Remediation with 99.9% Runtime

At every step, our team focuses on making our equipment powerful, versatile and easy to maintain. Our insitu remediation Multi-Phase Extractor 2700 Series is another example of our innovative design in action. Our integrated treatment system incorporates an oil/water separator and vacuum air stripper in one system, reducing maintenance. This extremely quiet unit makes it ideal for operation in residential areas.

Talk with the experts

To find out more about how we can fix your mining wastewater problem or remediation issue using proven, innovative systems, contact us.