Electro Separation Cell

Ultrafine Low Gravity Solids (LGS) Removal System

The ESC is the only process in the world that can remove colloidal solids consistently from Synthetic and Oil-Based Mud (OBM).

Ideal for offshore or onshore solids control on the rig, we get the ultrafines that centrifuges can't. With the ESC system you can program the desired density output to your exact customer density specifications. The result is exactly what you require, with low maintenance and huge savings.

Applications

- Solids control on the rig and spent mud treatment

- Removes ultrafines centrifuges can't

- Turnkey LGS removal system

- Offshore LGS removal

- Onshore LGS removal

ESG Innovations

- Reclaim drilling fluid for re-use

- Reduction of drilling fluid transported in

- Reduce sludge going to landfills

- Water reclamation

- Substantial reduction in CO2 emissions

- Extremely low energy usage

- Low environmental footprint

Sectors

Problems Solved

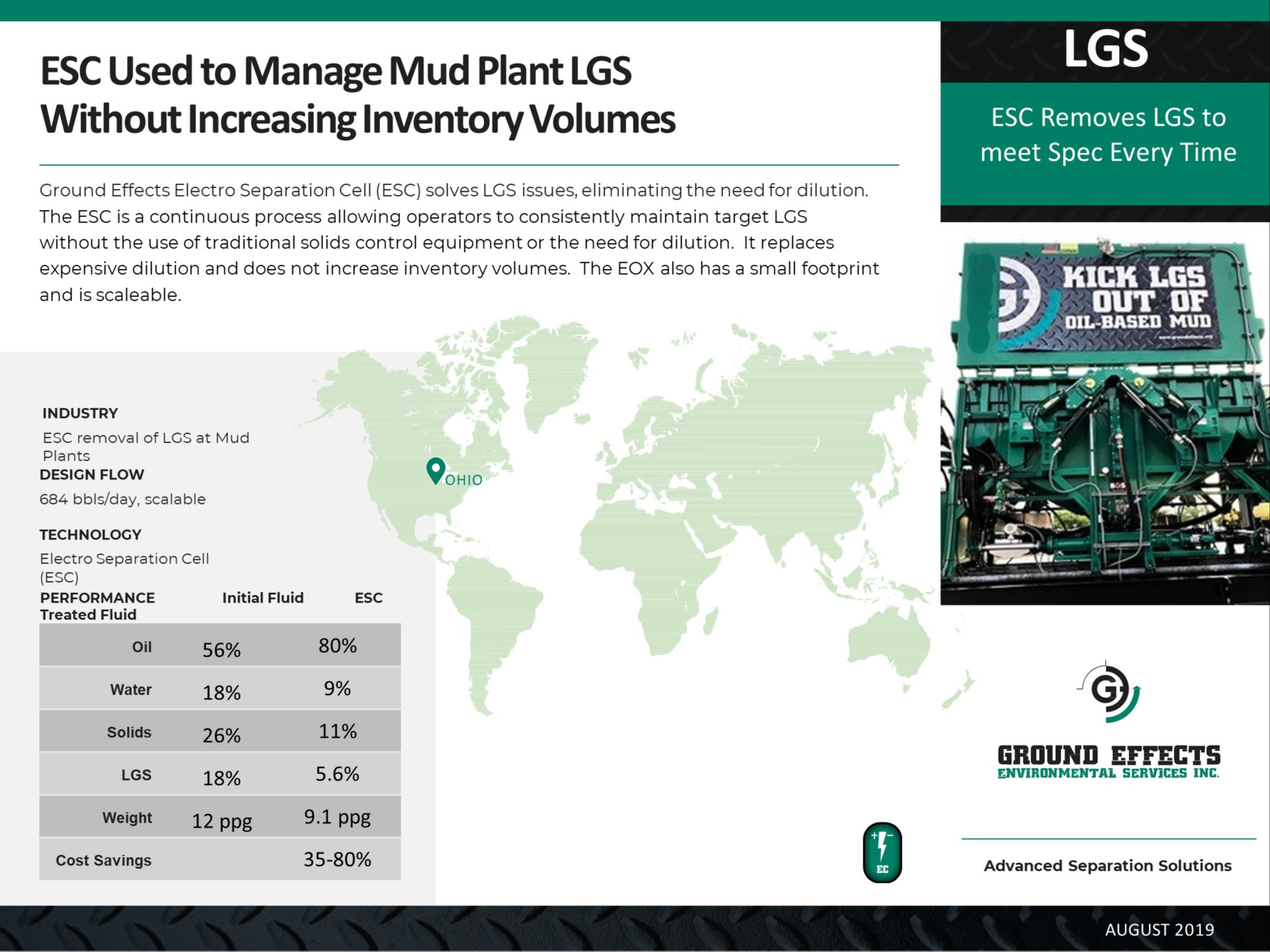

The Science Behind ESC

The ESC works on the principle of electrokinetics. Via proprietary coated electrodes, the ESC applies a high voltage electrical field to the Oil-Based Mud. The electrical field destabilizes the molecular bonds between the solids and the oil.

Through the destabilization process, the solids settle out as a result of gravity, and the oil rises where it is skimmed. The process does not use heat or chemicals and has very low energy use (1-2 kW/m3 of fluid processed).

Features/Benefits

Huge Savings

Save tens of thousands of dollars a day on solids control and waste management, on or offshore. Low maintenance and low consumables only increase your savings.

Easy Operation

Simply enter in the Electrical Stability of the fluid and the system automatically adjusts the voltage and amperage to optimize the process. The control package allows the operator to fine tune the machine for desired density output.

Advanced Optimization

Fine tune or optimize the ESC from anywhere in the world with our smartphone app for Apple or Android. You can set desired density output easily with one touch. Continuous monitoring ensures a consistent and reliable runtime and advanced troubleshooting control.

Desired Output Density

The operator can set the ESC to an exact density output to meet customer requirements. The ESC is fitted with our coriolis meter that measures flow, density and temperature so you know the exact outputs of the system with real-time data on your smartphone or with the Human Machine Interface (HMI).Technical Specifications

Area Classification: Class 1, Zone 2 (Option: Class 1, Zone 1)

| MODEL | Height | Width | Length | Weight | Electrical | Batch Volume | Capacity |

|---|---|---|---|---|---|---|---|

| 10M AXYS | 8'4" * (2.540 m) | 7'6" (2.286 m) | 16'6" (5.029 m) | 49,000 lbs (22,226 kgs) | 200 AMP, 480 V | 10m3 | 40-200m3/day |

| 6M AXYS | 8'4" (2.540 m) | 6'10" (2.083 m) | 16'6" (5.029 m) | 33,000 lbs (14,969 kgs) | 200 AMP 480 V | 6 m3 | 24-120 m3/day |

| 3M | 8'4" (2.540 m) | 6'10" (2.083 m) | 10'6" (3.200 m) | 17,000 lbs (7,711.1 kgs) | 100 AMP 480 V | 3 m3 | 12-60 m3/day |

| 1M | 6'0" (1.823 m) | 4'6" (1.372 m) | 6'0" (1.823m) | 8,000 lbs (3,628.7 kgs) | 60 AMP 480 V | 1 m3 | 4-20 m3/day |

| Control Module Common to all ESC's | 6'0" (1.823 m) | 3'6" (1.067 m) | 7'2" (2.184 m) | 3,200 lbs (1,451.5 kgs) |

System Characteristics

| Characteristic | Detail |

|---|---|

| Loading/Unloading Time | 10 minutes |

| Unloading Auger | Multi-directional Screw |

| Electrodes | Proprietary Coated Electrods |

| Electrode Wiper | 9,000 Force lbs; 4000 VPM |

| Electrode Vibrators | 9,000 Force lbs; 4000 VPM |

| Safety | Lid open shut off; low cell pressure shut off safety switch; high tank level shut off; low oil level shut off; high oil temperature shut off; DC rectifier; phase loss; thermal; over voltage trip; over current trip; cleared fuse; excessive program voltage; run dry protection; and high pressure shutdown |

Options

- Integrated air compressor

- Electrical configurations: 380/460/575 VAC – 50/60 Hz

- Class 1, Zone 1

- IECEx, UL, CSA, CE/ATEX certification

- Full electric drive

- Controls/compressor/N2/HYD Pack – containerized in NEMA 3R or purged DNV.2.7.1 rated container

- Remote telemetry

- DNV.2.7.1 rated skid or crash frame