Electrocatalytic Oxidation

EOX: Wastewater Treatment

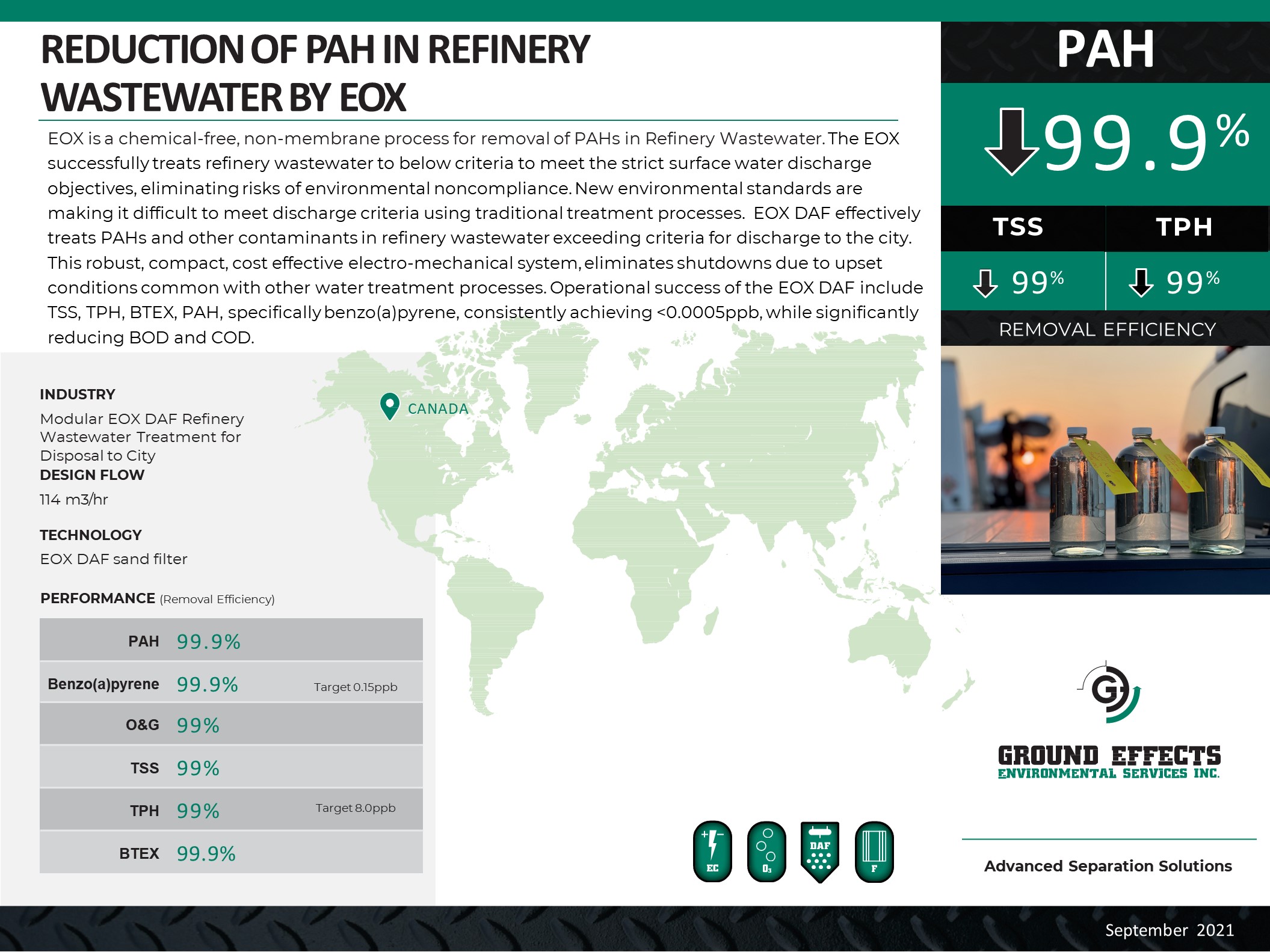

A GEE-patented technology, the Electrocatalytic Oxidation (EOX) treatment system is a chemical-free, turnkey contaminant removal process for wastewater.

The EOX combines high current electrocoagulation with high concentration ozone to create the most powerful advanced electrocatalyitic oxidation approach found anywhere. Mobile, modular or fixed plant, the EOX achieves broad-spectrum contaminant removal without the use of chemicals.

Complete with its own auto-clean system, it’s the ultimate wastewater treatment system for oil & gas, industrial, mining, municipalities and agriculture industries.

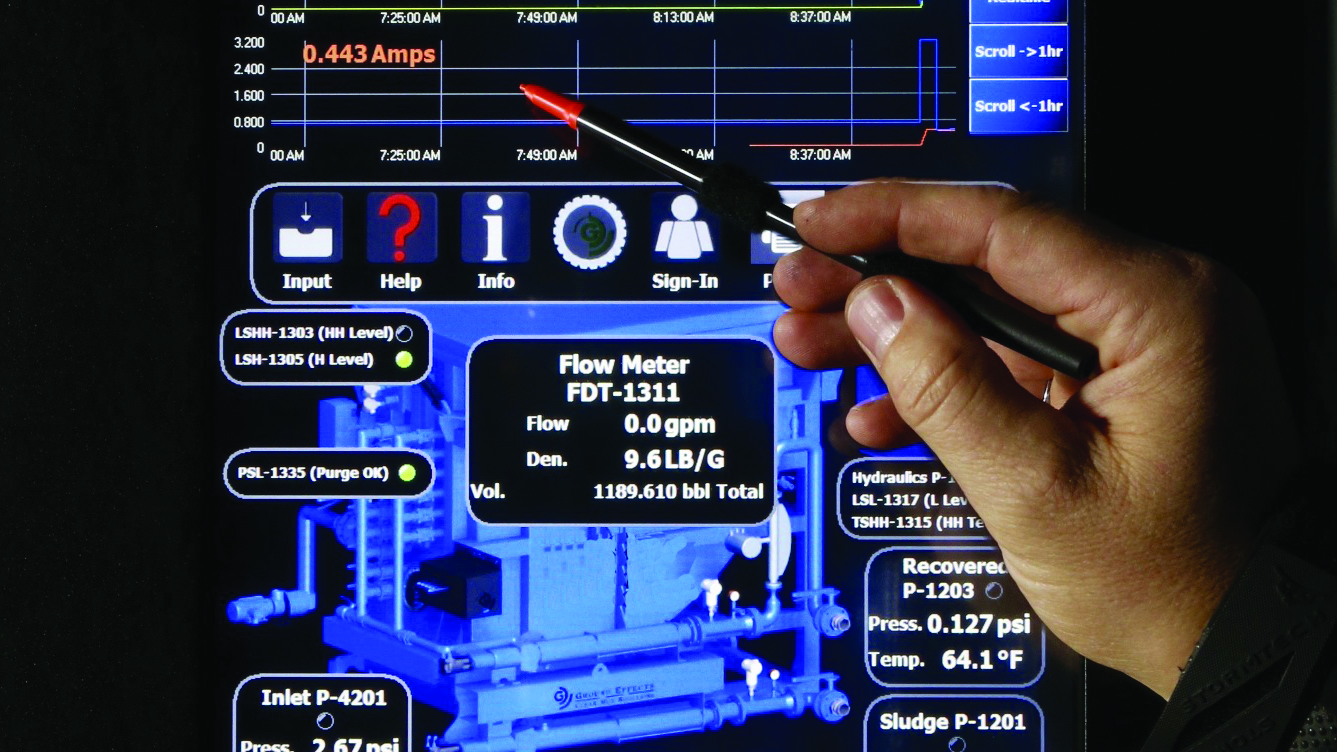

The EOX is scalable to any flow rate required and can be optimized or monitored from anywhere in the world through our mobile app for Apple or Android.

Applications

- Oil & Gas / Industrial

- Oil

- Emulsions

- H2S

- Silica

- Total Suspended Solids (TSS)

- Municipal Wastewater Treatment / Agriculture

- Phosphates

- Total Suspended Solids (TSS)

- Ammonia

- Bacteria

- H2S

- Endocrine disruptors

- Pharmaceuticals

- Scalable: 0 - 50,000 m3/day

(0 - 13,230,000 gallons/day)

ESG Innovations

- Significant reduction in water usage

- Reduce or eliminate need for tailing ponds

- Significant reduction in water trucked in

- Extremely low energy usage

- Low environmental footprint

- CO2 emission reduction associated with H2O trucking

Sectors

Problems Solved

The Science Behind the EOX

The EOX works on the principle of electrokinetics.

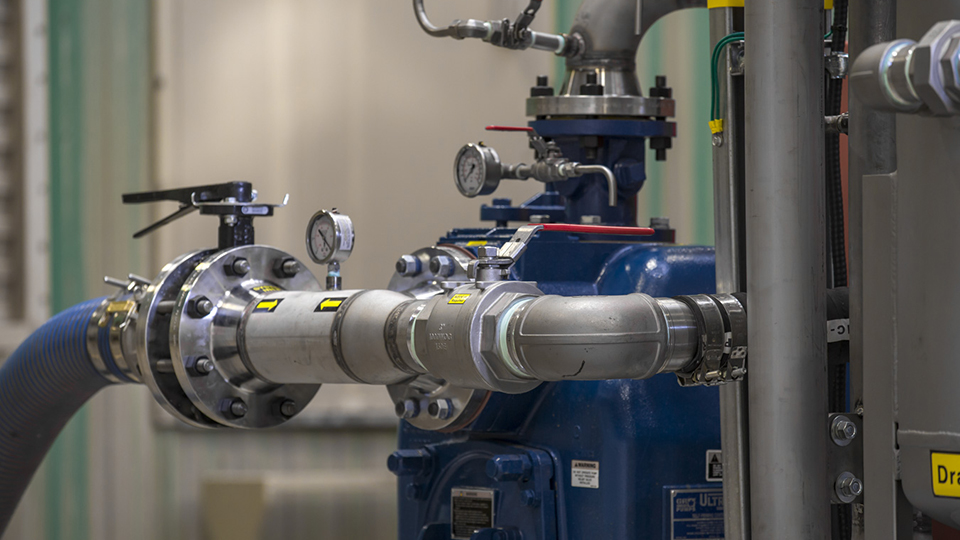

Via proprietary electrodes, the EOX applies a high current electrical field to the wastewater. The electrical field destabilizes the molecular bonds between the contaminants and the water.

Through the destabilization process, the waste separates from the water and is removed, leaving the clean water.

The process does not use heat or chemicals and has very low energy use and a compact footprint.

Benefits

Increased Contaminant Removal

The EOX employs our robust Hydroxyl Oxidation Reactor, which uses the highest ozone concentration (20% wt. vs. typical 5% ozone) to pressurize the wastewater and increase contaminant removal. The pressurized ozone remains in microbubble state for increased contact and reactivity. The system’s unique cyclonic mixing results in increased mass transfer.

High Flow Rates

The EOX’s EC reactor is a unique pressurized system that reduces residence time from 1 hour to 30 seconds with no foaming or sludge. It’s a low maintenance system component that results in high flow rates and no downtime.

Self-Contained, Turnkey Operation

The EOX is a self-cleaning, low maintenance system with an intuitive and easy to use Human Machine Interface (HMI) resulting in a one-person, turnkey system.