Electrokinetic Remediation System

The GEE EK3 Electrokinetic Remediation System is a proprietary in situ remediation process for salts, metals, hydrocarbons and chlorinated hydrocarbons in soil and ground water. A GEE-patented technology, the EK3 is an extremely effective and proven alternative to the ‘dig and dump’ approach to groundwater and soil contamination. The EK3 can be used to distribute chemical oxidation and/or biosupplements for hydrocarbon remediation in clays and silt.

Mobile and compact, the EK3 is scalable to any soil or groundwater remediation problem you may have — no matter how large or deep. The EK3 uses low-voltage direct current (DC) to remediate the ground and soil contamination well below criteria with low consumables and low maintenance.

It’s fast, cost-efficient and can be optimized and monitored easily from your mobile phone. It’s the best onsite salt remediation treatment system on the planet.

Applications

Oil & Gas

- Uniform distribution chemical oxidation for hydrocarbon remediation

- Low permeability soil and groundwater remediation

- Flare pits

- Drilling waste sites

- Other spills including flowline/pipeline breaks

- Upstream Oil and Gas Industry including refineries, oil and gas drilling sites, oil and gas battery sites, flare pits and other spills

- Downstream Oil and Gas Industry including gas stations and bulk fuel storage facilities

Municipal

- Salt storage yards

Industrial

- Former Manufactured Gas Plants (FMGPs)

- Asphalt plants

- Former steel and coke plants

- Industrial practices including wastewater full of lead, zinc, copper and nickel

Mining

- Cyanide and mercury contamination

Sectors & Applications

The Science Behind the EK3

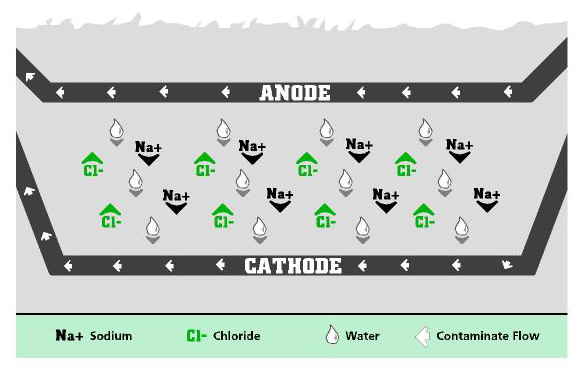

EK3 is a horizontal electrokinetic remediation system. Via proprietary electrodes, the EK3 applies a uniform electrical field to the groundwater and soil. The electrical field destabilizes the molecular bonds between the contaminants and the water. The process does not use heat or chemicals and has very low energy use and a compact footprint. The EK3 system can remediate a wide variety of contaminants in silt and clay.

Benefits

Proven In Situ Salt Remediation

EK3 is the only product in the world that can remediate salt—and other contaminants— from soil and groundwater cost-effectively in situ. The system works in low permeability soils (such as clay)—increasing the applications and uses.

More Effective Than ‘Dig n’ Dump’

The EK3 costs less than the "dig and dump" process, with less manpower, no trucking, less disturbance to the site and less insurance to cover all the moving parts and people.

Any Area, Any Depth

GEE’s EK3 system can remediate large areas at any depth, quickly. Talk with us today about a presentation.

Compact Footprint

The EK3 targets the contaminated zone effectively with minimal above ground infrastructure, site disturbance and environmental impact. The result is a highly effective remediation system for large sites without the traffic and onsite disturbance.EK3 VS. DIG N' DUMP

| GEE’s EK3 | Dig ‘n’ Dump |

|---|---|

| Cost: $20-80/m3 | Cost: $100-180/m3 |

| Treats the problem in situ. | Moves the problem. |

| Low public visibility: less chance of negative public perception. | High public visibility: increased chance of negative public perception. |

| Minimal site disturbance. | Creates a large construction site and requires a large construction crew. |

| Minimal greenhouse gas emissions. | Significant greenhouse gas emissions created by excavation equipment. |

| Reduced traffic. No road development or upgrades necessary. Remote access possible. | New road construction or upgrades to access the site because of increased traffic. |

| No dust and disturbance to neighboring properties. | Continual dust and disturbance for neighbouring properties. |

| Low travel costs. | Enormous transportation and travel costs. |