Multi-Phase Extractor Extra Performance

Compact & Powerful Multi-Phase Extraction at a Lower Cost

At GEE we decided to take our most powerful Multi-Phase Extractor (MPE) and make it the smallest powerhouse in the industry. Meet the MPE-XP (Extra Performance). The XP contains our most innovative MPE thinking in an extremely small system (12 feet by 6 feet, to be exact). With the same power and efficiency (a 99.9% runtime) of a larger GEE model, the MPE-XP is perfect for any in situ remediation in either hot or cold climates. And the biggest thing about the XP…is its small price. The MPE-XP can be tailored for warm or cold climates ranging from -40 degrees Celsius and above.

Applications

Oil & Gas

- In situ

- Drilling Waste Sites

- Other spills including flowline/pipeline breaks

- Upstream Oil and Gas Industry including refineries, oil and gas drilling sites, oil and gas battery sites, flare pits and other spills

- Downstream Oil and Gas Industry including gas stations and bulk fuel storage facilities

Municipal

- Retired gas stations, fuel/refinery sites, spills

Industrial

- Former Manufactured Gas Plants (FMGPs)

- Asphalt Plants

Sectors

Problems Solved

The Science Behind the MPE-XP

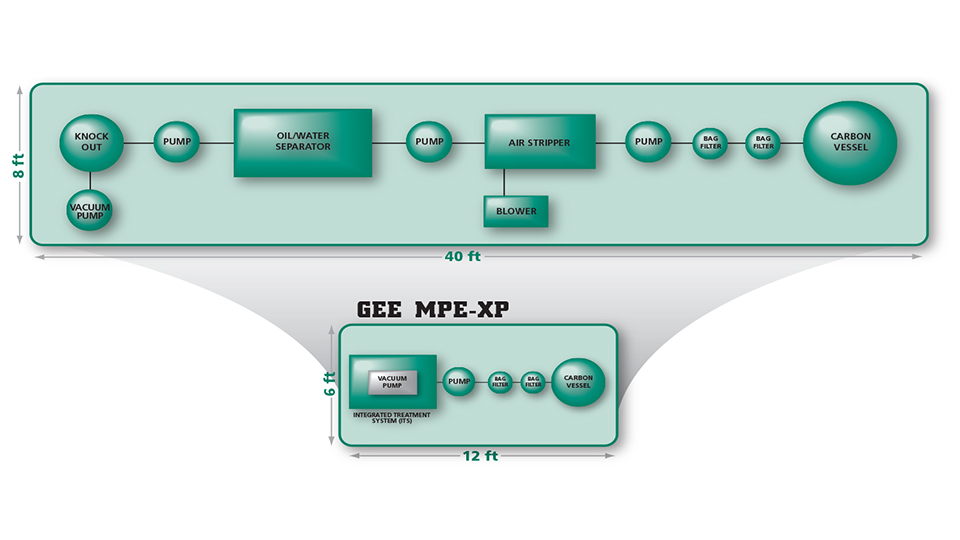

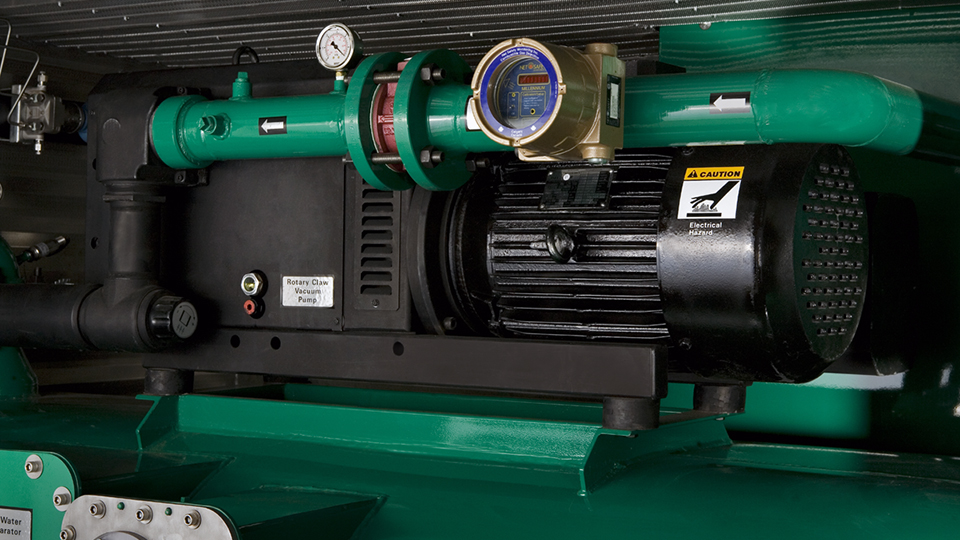

At GEE we innovate; we don’t imitate. We gave ourselves the challenge to fit the same MPE innovation and 99.9% runtime reliability into a smaller version. We re-designed all the components to be smaller without losing efficiency. We could make it compact through our Integrated Treatment System (ITS) that incorporates and oil/water separator and vacuum air stripper. With 300% fewer parts than regular industry MPEs, the result is a Multi-Phase Extractor that can run quietly in residential areas and yet is versatile and robust enough to handle hot climates or arctic climates.

Features

99.9% Runtime

Downtime means upped expenses. Our MPE-XP boasts a 99.9% industry-leading runtime due to efficient design

Compact Footprint

The GEE MPE-XP is 12’ x 6’ and so compact it’s easy to transport in a sea container or freight trucking system; three XP’s can go in a container and it only takes three palette spaces in a truck.

Optimize from Your Mobile Phone

You can easily optimize, download performance data and get alerts through our smartphone app for Apple or Android, or from your desktop.

Low Maintenance

The MPE-XP boasts 300% fewer parts than industry-standard MPEs. Fewer moving parts means less breakdowns.Compare & Contrast

| GEE MPE-XP (15 HP) | Industry-Standard MPE (15 HP) |

|---|---|

| 12’ by 6’ MPE with water treatment | 40’ by 8’ MPE with water treatment |

| Easy to ship: 3 systems fit in one 40’ X 8’ shipping container | More expensive to ship: 1 industry-standard system is the same as shipping 3 XPs |

| Integrated Treatment System (ITS) | • Component treatment: knockout, slant plate clarifier, oil/water separator, air stripper, etc. |

| Custom-built sound-attenuated enclosure. Fits on compact trailer (optional) | Shipping container |

| 99.9% runtime | 50-70% runtime |

| Touch screen controls | Touch screen controls |

| Requires smaller thermal/catalytic oxidizer | Requires thermal/catalytic oxidizer twice the size |

| No additional air treatment from air stripper required | Requires additional air treatment from air stripper |