LGS Removal on Spent Drill Mud by ESC

Ground Effects successfully deployed the Electro Separation Cell Technology to treat spent fluid from the Eagle Ford formation in Texas. Low gravity solids in the feed mud, totaling 13%v/v, were reduced to 1.5%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

The Situation

The continued expansion of drilling operations in the Eagle Ford formation in Texas, will continue to focus on the minimization of unscheduled events and

downhole nonproductive time. The drilling environment into tight shale alone places serious demands and constraints on both the engineering and application

of drilling fluids employed in well construction operations.

Extended reuse of drilling fluid systems results in extensive accumulation of low gravity solids (LGS) to the point where they cannot be removed by conventional solids control equipment. Buildup of ultra fine LGS can create serious issues. Failure to adequately address these can result in excessive cost overrun or even loss of the well.

Typical options to reduce this risk are to dilute the fluid system, creating three or four times the original volume, or disposing of the fluid system and building a new system from scratch. Both options are extremely expensive.

In Texas, major issues arise that affect the drilling operations such as reducing the rate of penetration, differential stick of the drill pipe and loss circulation. These can cause substantial time lost and have a large economic impact. OBM waste is often stored in fixed facilities and becomes a liability over time.

The Solution

The Electro Separation Cell (ESC) technology, recovers valuable base oil for reuse and/or resale. The ESC uses electrokinetics to destabilize the bonds

within the OBM emulsion and separates out the base oil from the native clays and drilling solids. The ESC focuses on colloidal and ultra fine LGS of

less than 6 microns. The result is clean base oil.

The reduction in costs and improvement of operational efficiencies is substantial. There is a 60-70% reduction of waste produced, reducing storage, disposal and transportation costs.

The Results

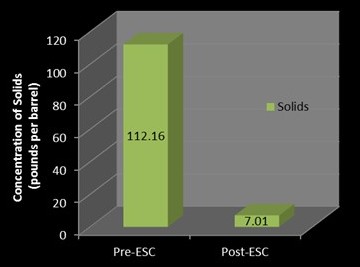

Other key performance indicators achieved by the ESC Technology during this treatment process were:

- Recovered oil quality unchanged from original

- OBM properties

- before ESC: 69.5/17.5/13% oil/%water/%solids

- after ESC: 98.5/0/1.5% oil/%water/%solids

- Approximately 27,954kg of solids removed per day equivalent to 10M system

- Density of recovered base oil 7.00ppg

- Processing Rate between 11-22GPM (377 and 754 bbl per day), equivalent 42-83LPM (60-120 m3 per day), equivalent

- Recovered base oil now available for dilution of other drill fluids

- Disposal volumes reduced by 60-70%

- Reduced the costs and liability associated with storage, transportation and disposal of full fluid volume

- Proven, viable solution for dealing with high LGS content fluid systems

The ESC technology treated Eagle Ford formation spent OBM in Texas.

- LGS in feed mud reduced from 13% to 1.5% v/v

- Approx. 27,954kg of solids removed per day equivalent to the 10M system

- Final density 7.00ppg

- Process rate 60 to 120 meters3 per day equivalent, to the 10M

- Disposal volumes reduced by 60 to 70%

| ESC Run Capacity per Unit | 1M | 3M | 5M | 10M |

|---|---|---|---|---|

| Gallons per minute (GPM) | 1.1 to 2.2 | 3.3 to 6.6 | 6 to 11 | 11 to 22 |

| Barrels per day (BPD) | 38 to 76 | 113 to 226 | 189 to 377 | 377 to 755 |

| Liters per minute (LPM) | 4 to 8 | 12.5 to 25 | 21 to 42 | 42 to 83 |

| Cubic meters per day (m3/day) | 6 to 12 | 18 to 36 | 30 to 60 | 60 to 120 |