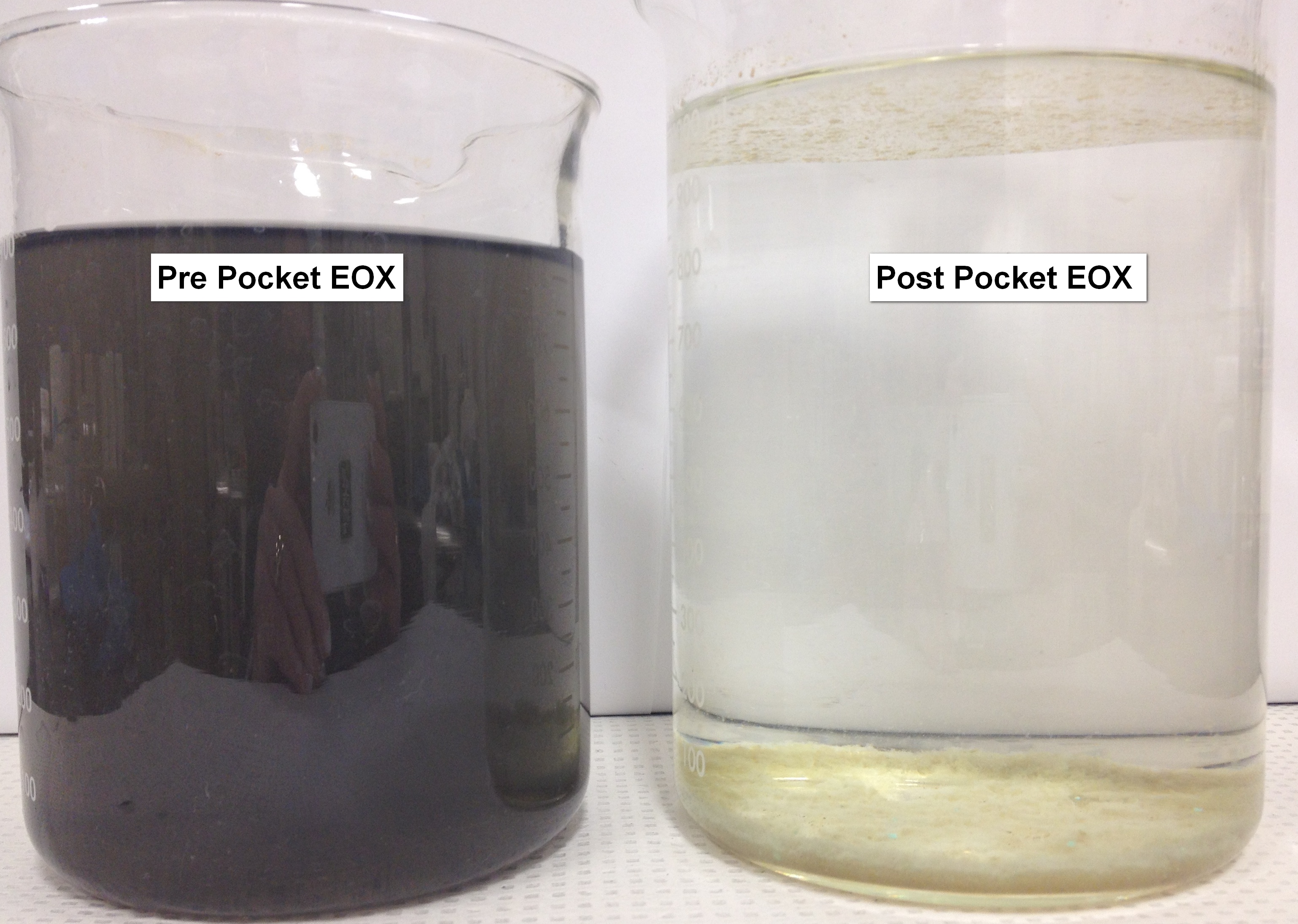

Pocket EOX

The Pocket EOX: Safe, Clean Drinking Water in Minutes

The GEE Pocket EOX is an easy-to-use pocket-sized water treatment system anyone can operate off a mobile phone, solar panel or scooter battery.

Developed for people struggling with unsafe drinking water, these units are designed for individuals to treat their own contaminated drinking water in a matter of minutes.

We provide Pocket EOX units to charities at no-profit to us. Hundreds have already been shipped to different parts of the world from the post-cyclone crisis in Mozambique to developing countries where unsafe drinking water is a daily struggle.

A Recent Letter

“Dear Ground Effects, the units are all still in use in Rwanda and Kivu Province of Congo next door. People are very happy with the improvements in their health and more productive lives as a result. A medical doctor told me that a patient with health problems over many years has overcome all of his health challenges since he has been using the Pocket EOX with a small solar panel. The doctor is amazed and would like to test further in the 14 bush clinics he supervises.

“Dear Ground Effects, the units are all still in use in Rwanda and Kivu Province of Congo next door. People are very happy with the improvements in their health and more productive lives as a result. A medical doctor told me that a patient with health problems over many years has overcome all of his health challenges since he has been using the Pocket EOX with a small solar panel. The doctor is amazed and would like to test further in the 14 bush clinics he supervises.

The devices are very precious and people are being careful to look after them so there have been no breakdowns or mechanical problems. The most popular source of power is the small solar panel since there is no electricity in many rural areas. We could certainly use more if and when they are available. Thank you very much for your assistance. It has really changed lives.

The Science

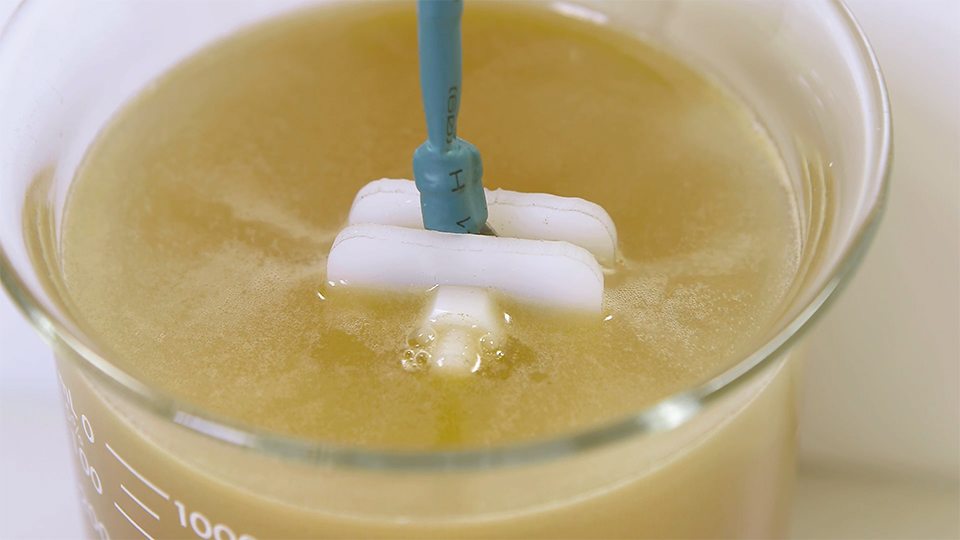

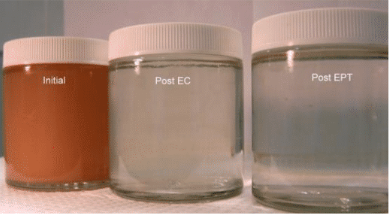

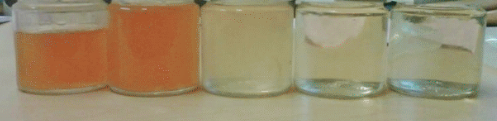

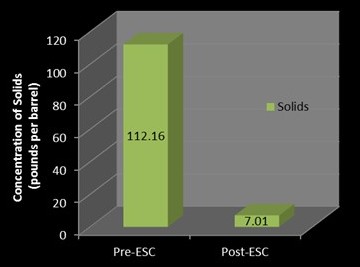

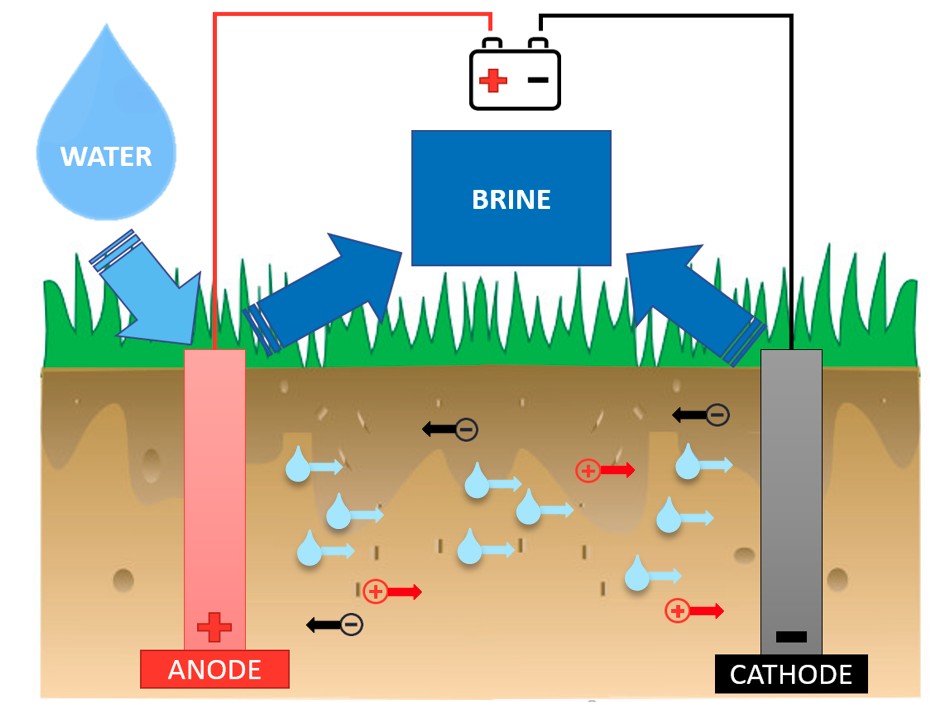

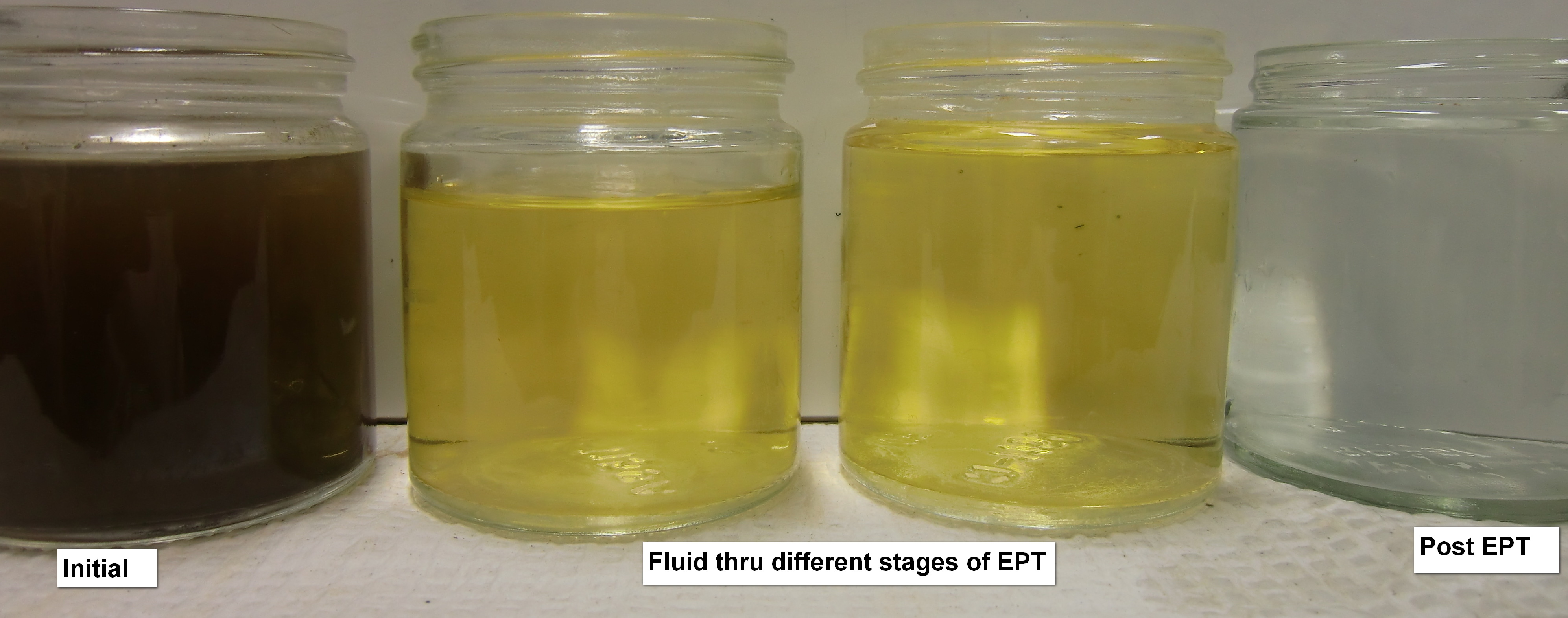

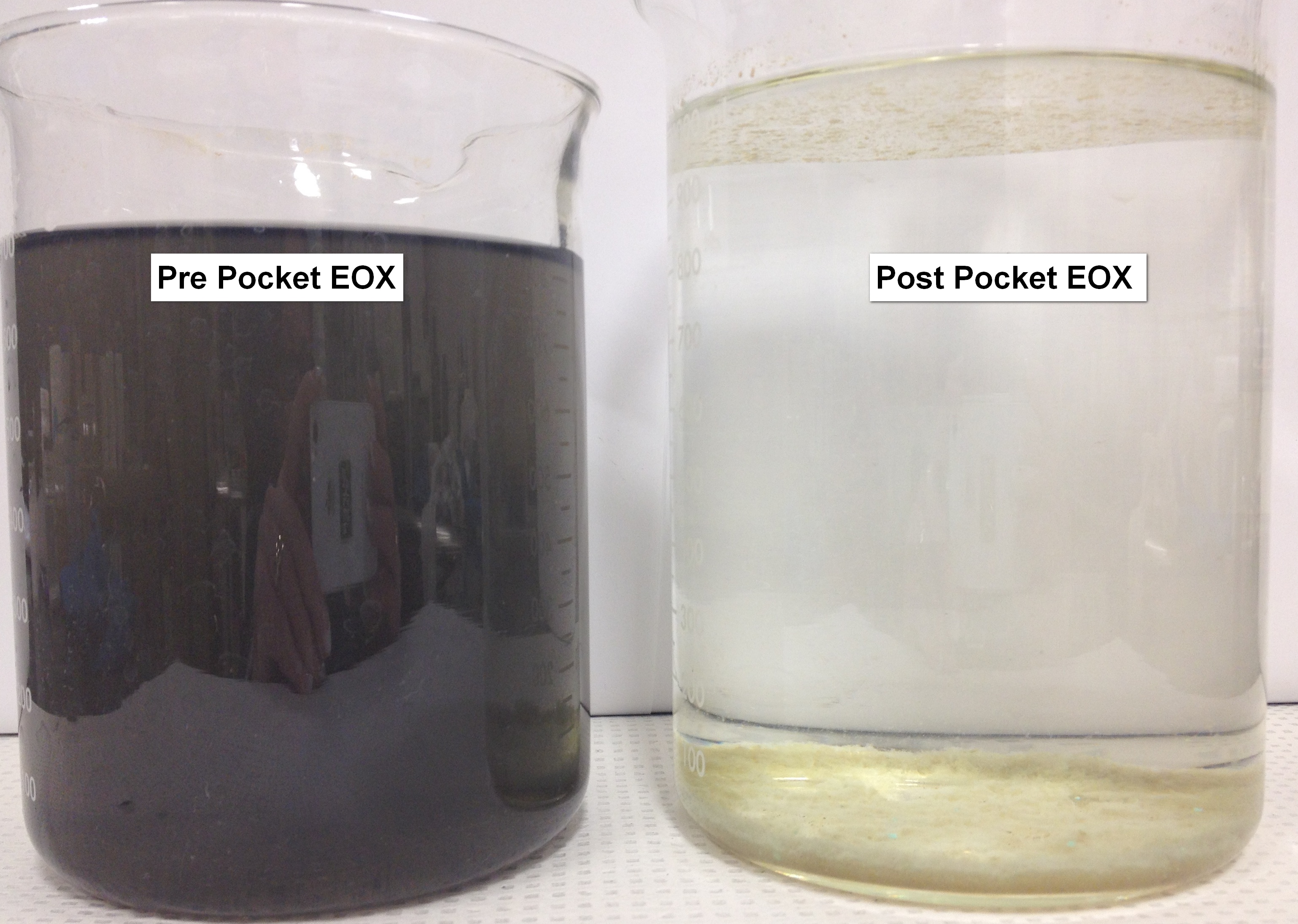

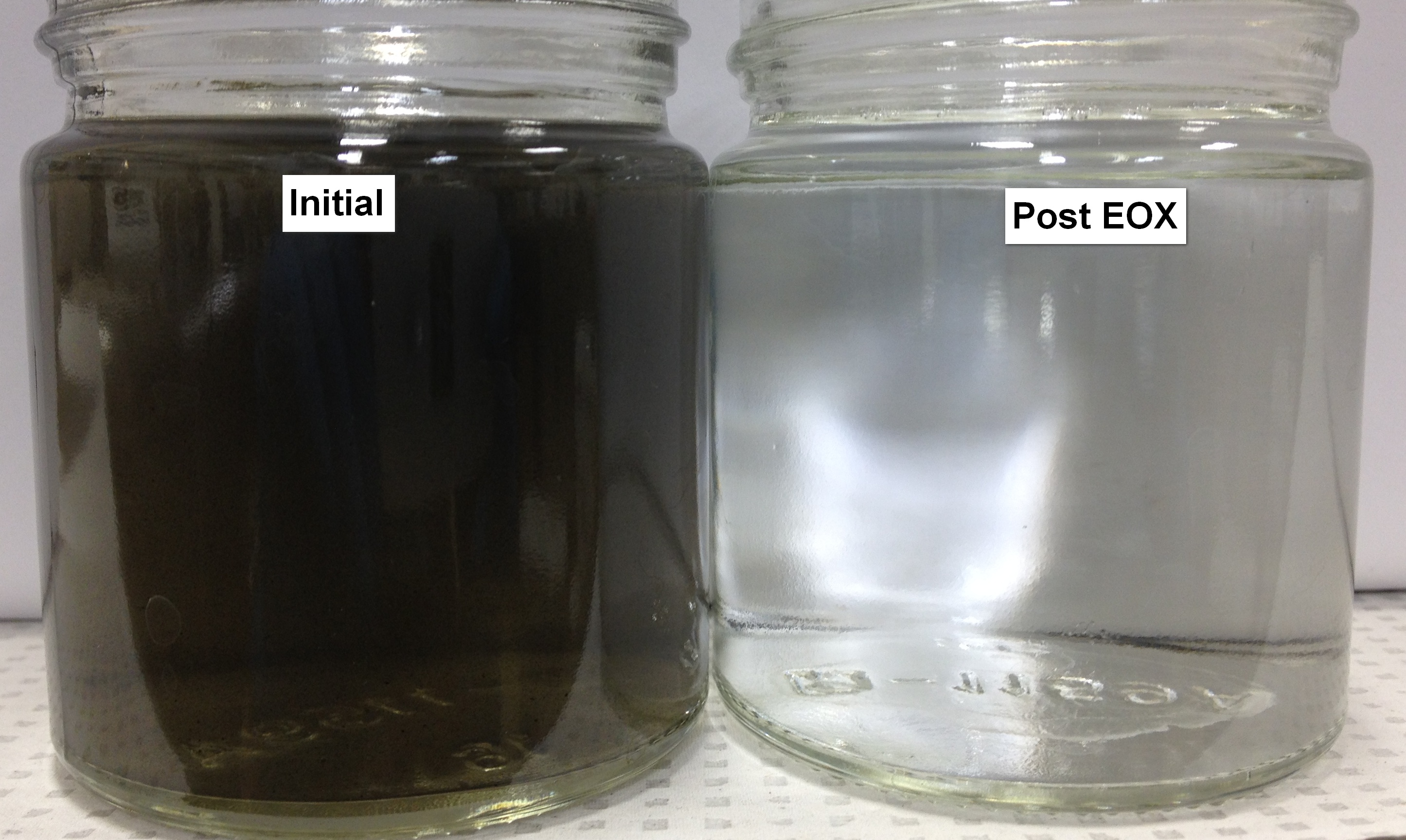

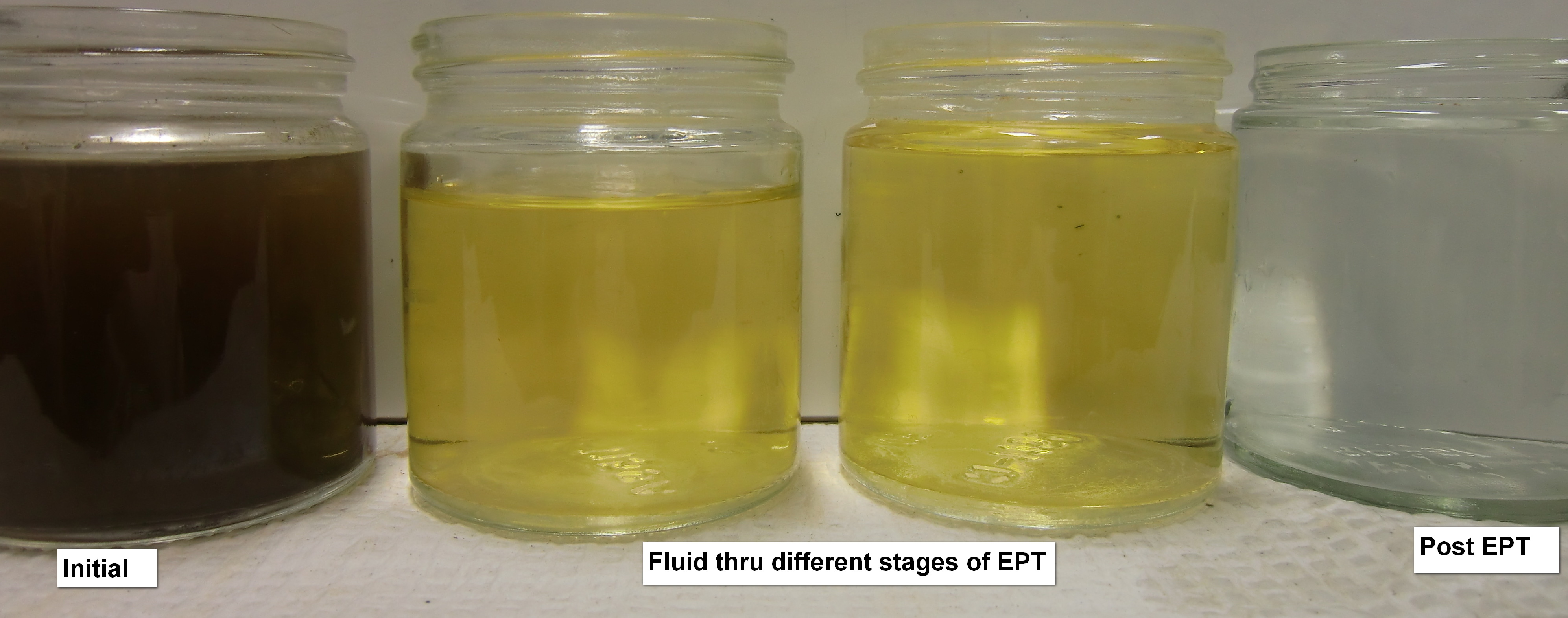

GEE’s Pocket EOX is based on our EOX wastewater treatment technology we use in a variety of industries. The Pocket EOX works on the principle of electrokinetics.

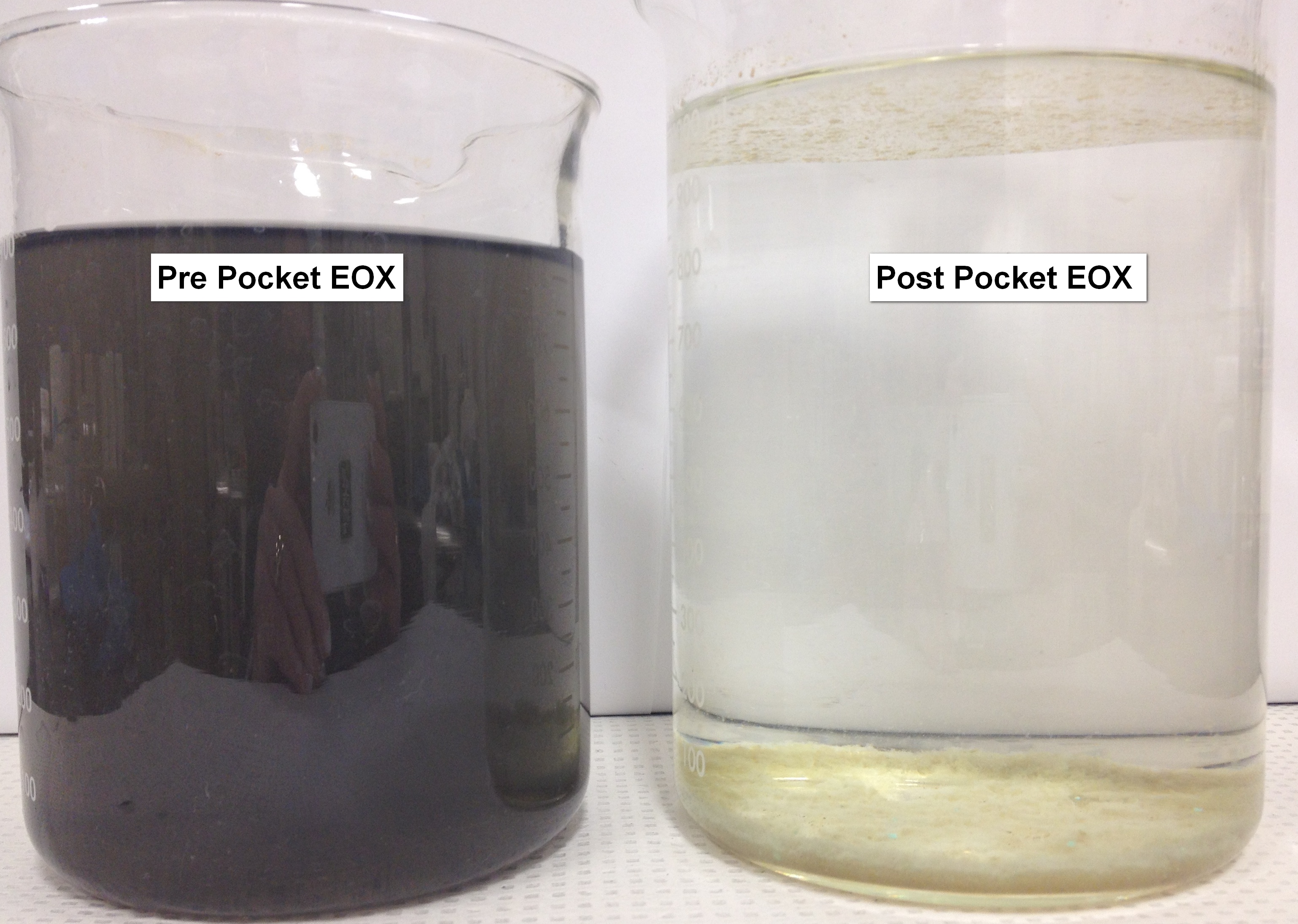

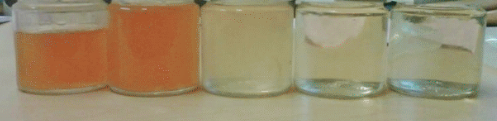

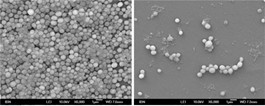

Via proprietary electrodes, the EOX applies a safe low current electrical field to the wastewater. The electrical field destabilizes the molecular bonds between the contaminants and the water in minutes. Through the destabilization process, the waste separates from the water and is removed, leaving the clean water. The process does not use heat or chemicals and has very low energy use.

Features

Safe Drinking Water in Minutes

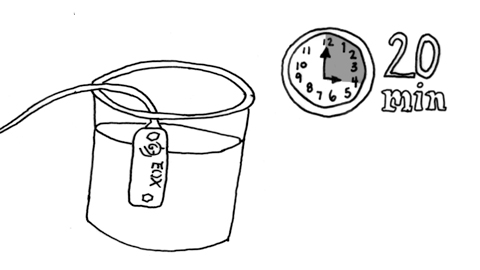

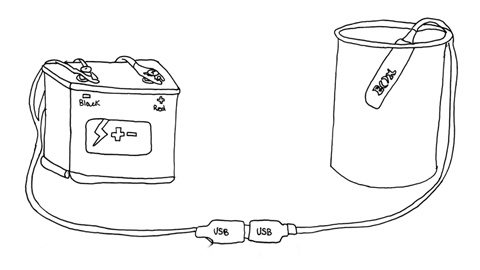

Can treat five gallons of water in 20 minutes removing bacteria, viruses, arsenic, cyanide, ammonia, phosphates, metals, suspended solids and many more contaminants.

Easy to Use

The system is simple, effective and portable. It has no moving parts, no membranes and uses no chemicals.2018_480x270.jpg)

No Language Barrier

The Pocket EOX is delivered with an illustrated brochure so that the process can be understood by non-readers or non-English-readers.

Accessible, Readily Available Energy Sources

Requires two watts of electricity and can be charged using a car battery, scooter battery, cell phone battery backup or charger, or solar panel.Case Studies

Bacterial Elimination in Contaminated Drinking Water in Kenya by Pocket EOX Technology

Kenya

GEE has successfully deployed the Pocket EOX in rural communities in Kenya, eliminating both total and fecal contamination in water, now making the water safe to drink.

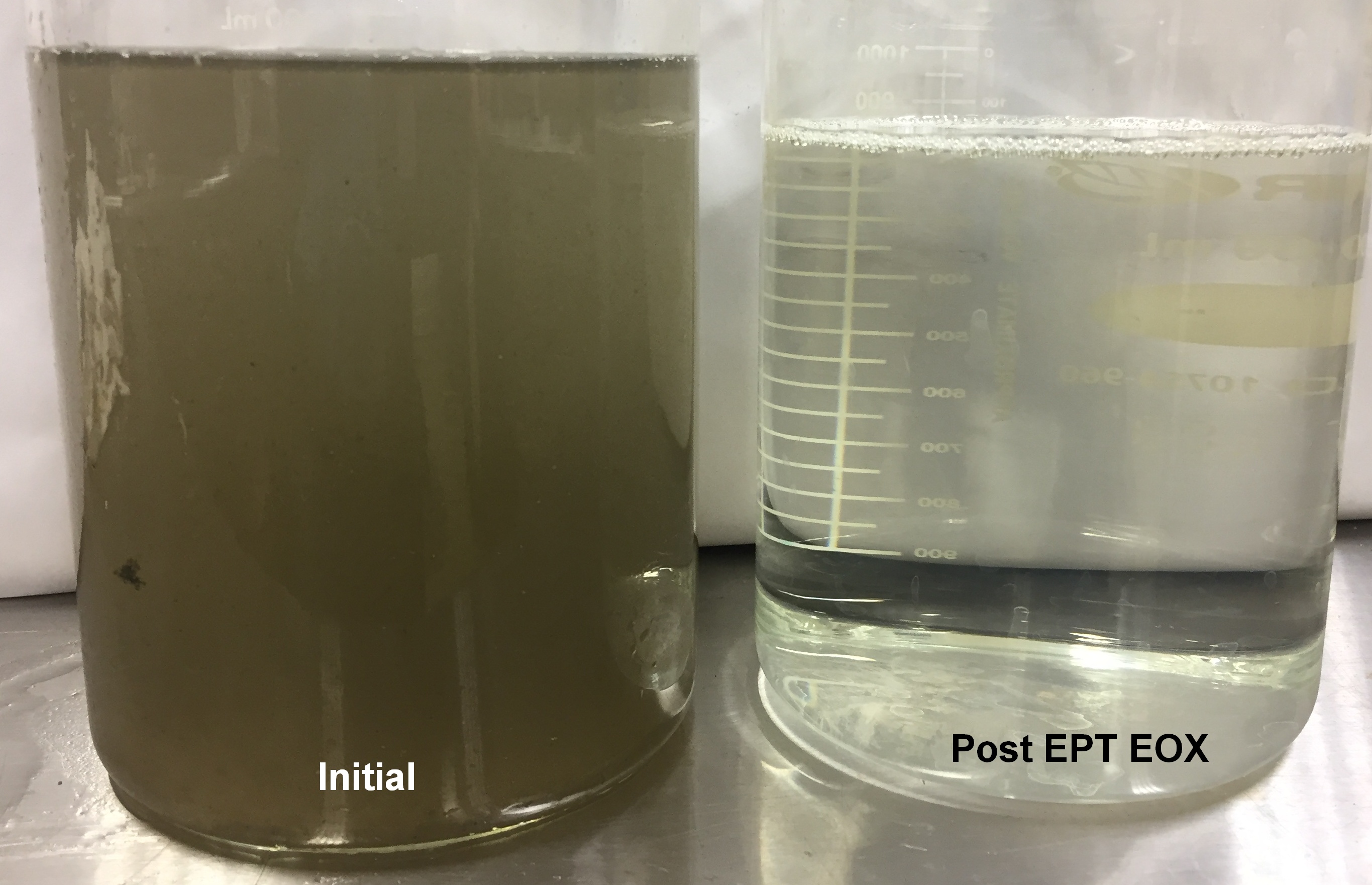

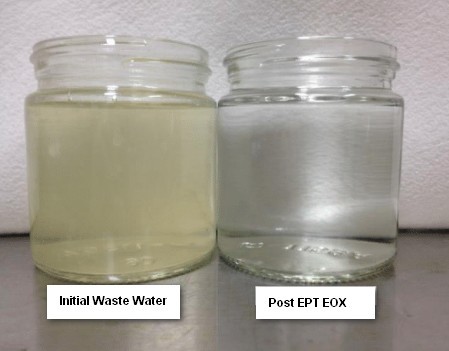

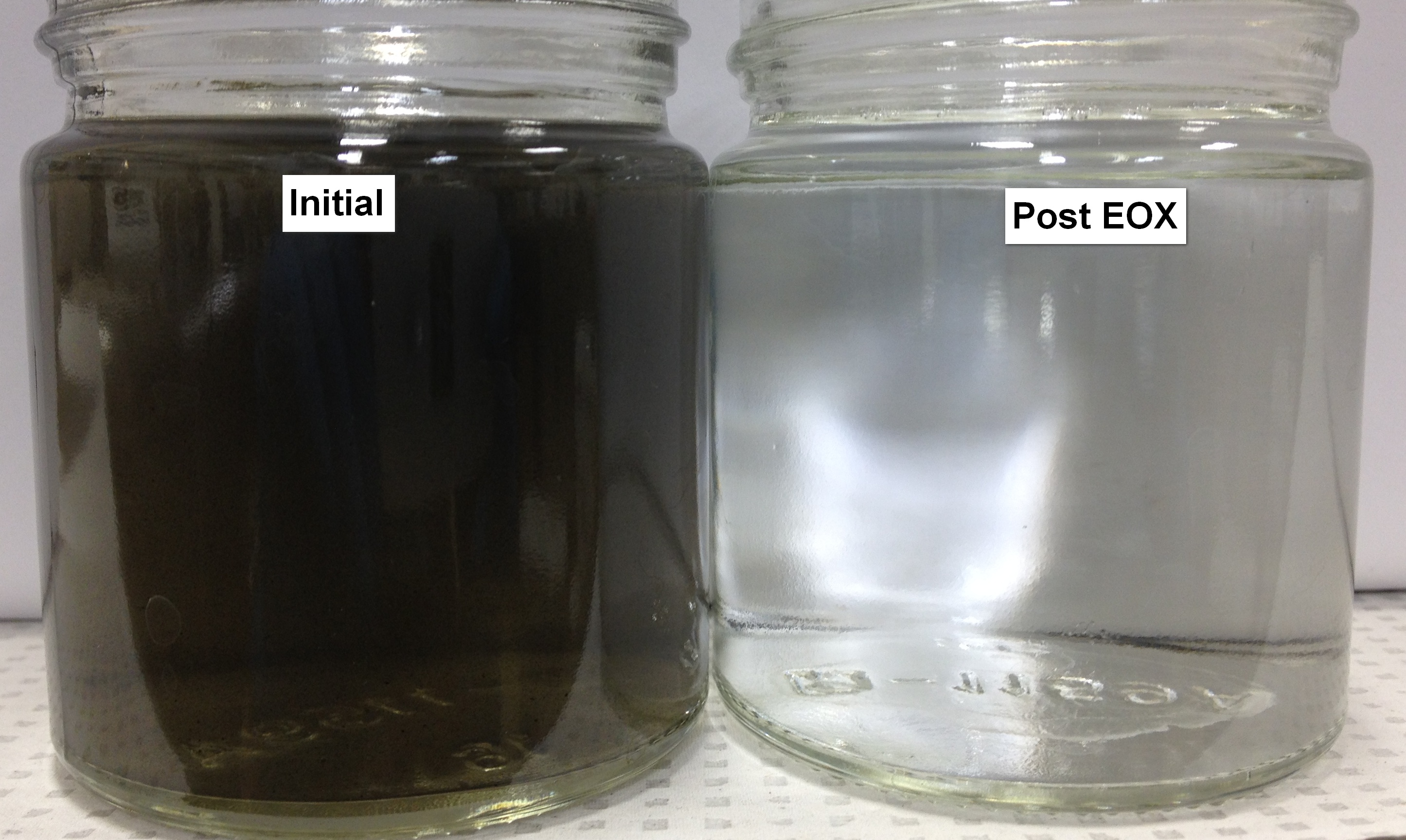

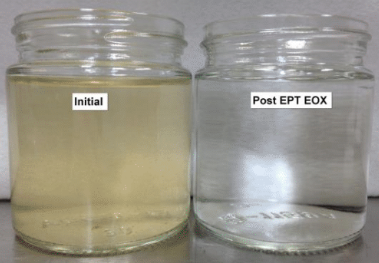

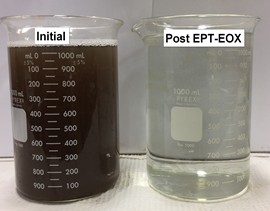

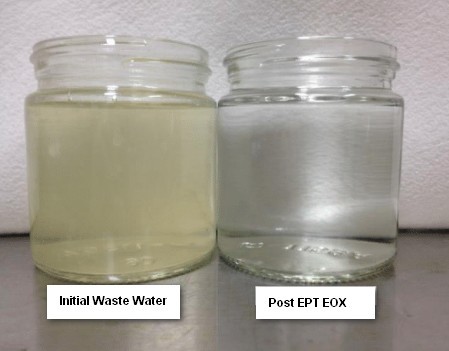

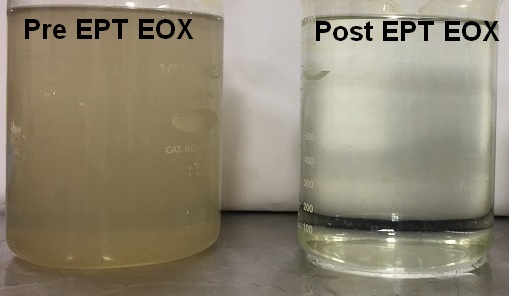

High Phosphate Wastewater Treatment By EPT EOX

British Columbia

High phosphate wastewater from municipal plants reduced by 99.6% using EPT EOX Solution

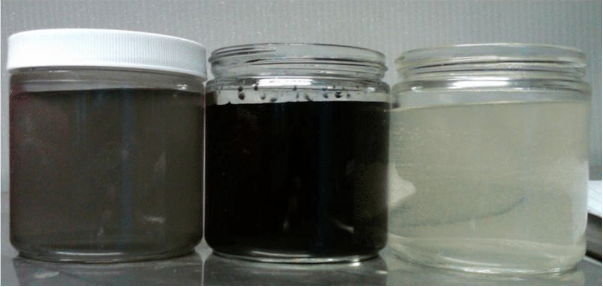

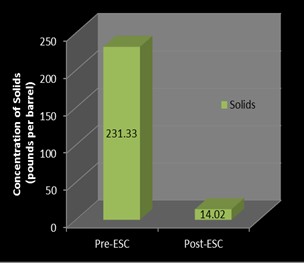

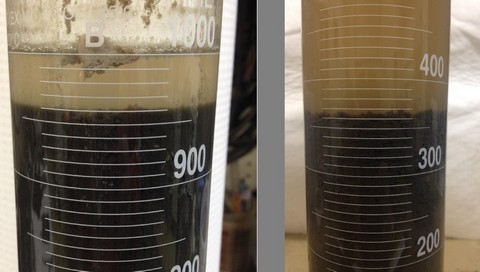

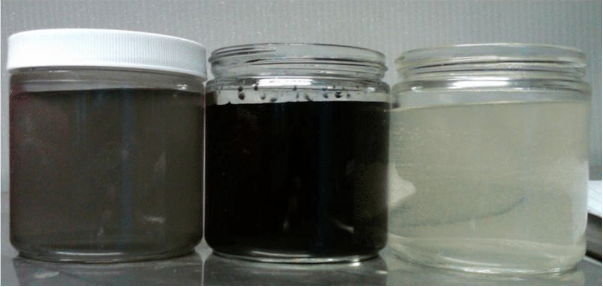

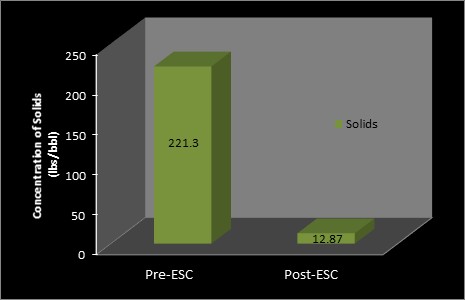

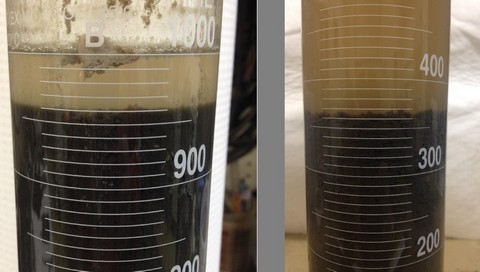

200 BBL Comparison ESC vs Centrifuge

West Texas, USA

Head to Head, equal amounts of fluid-direct comparison. Ground Effects ESC significantly reduces mud weight by removing LGS, while decreasing sludge volumes, reducing waste by half.

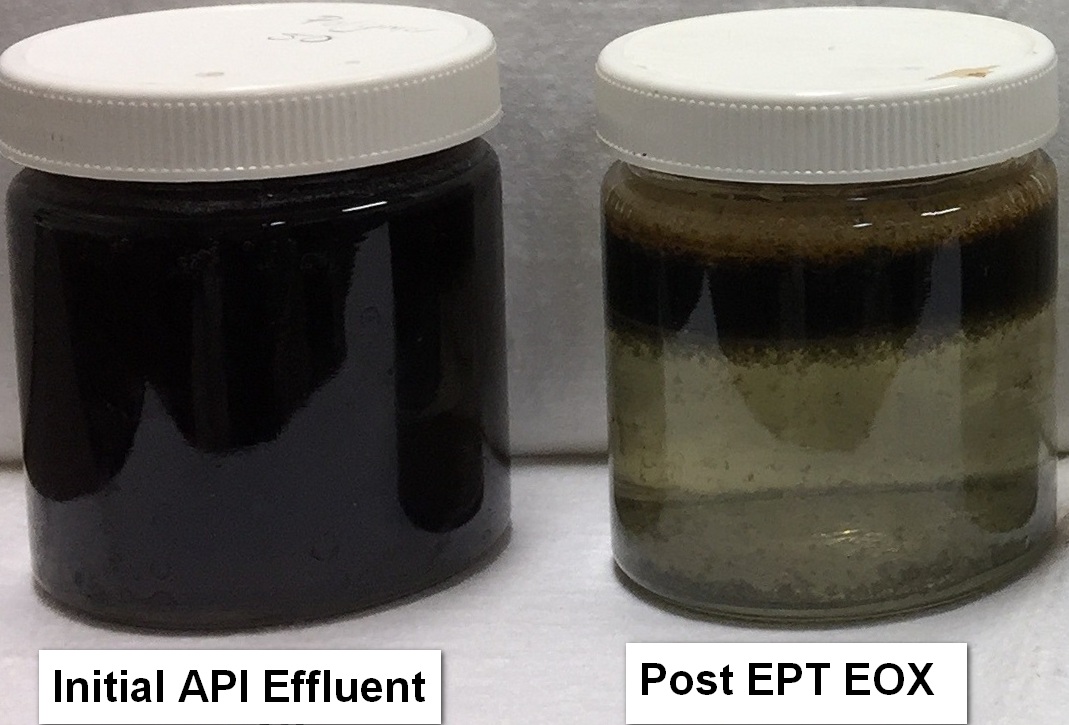

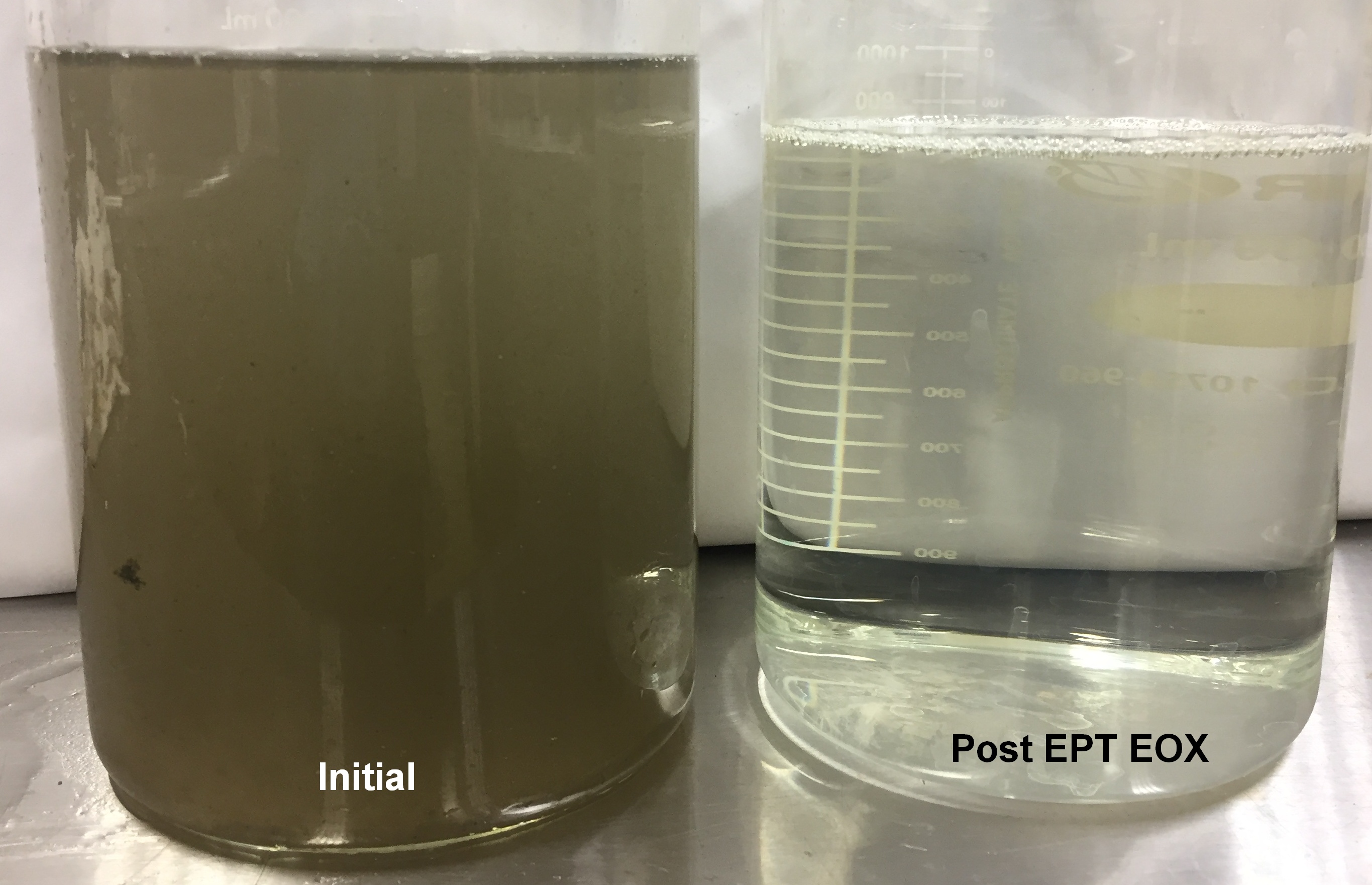

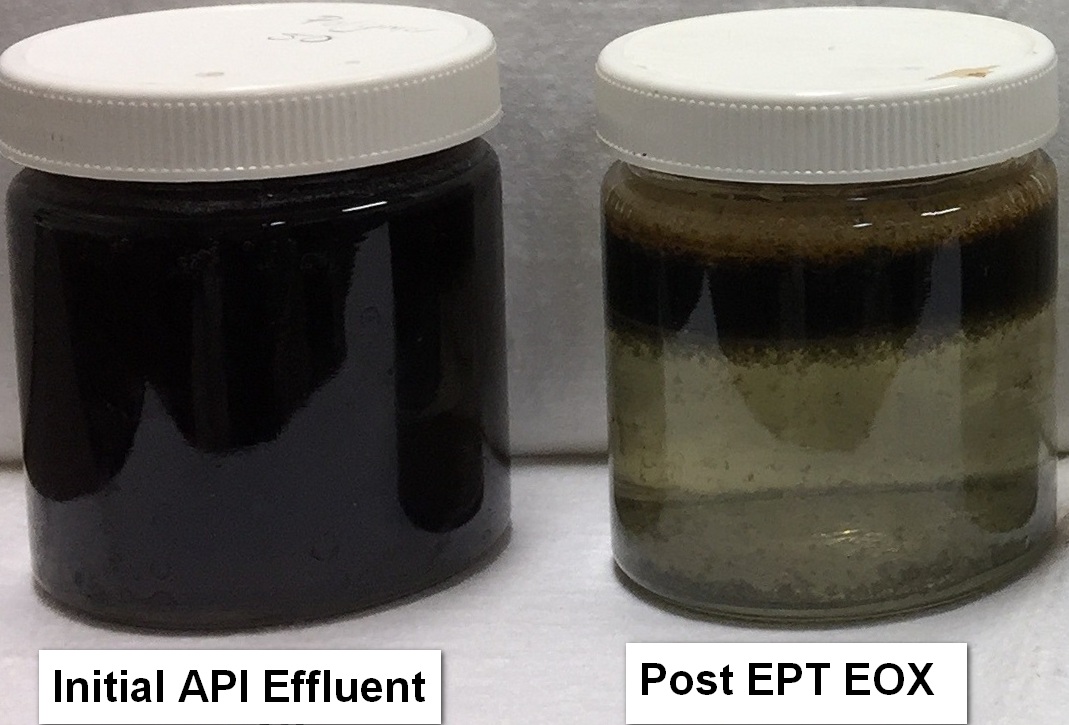

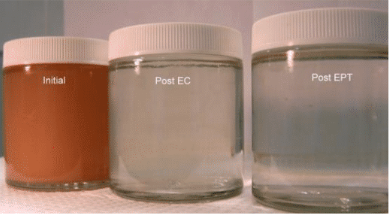

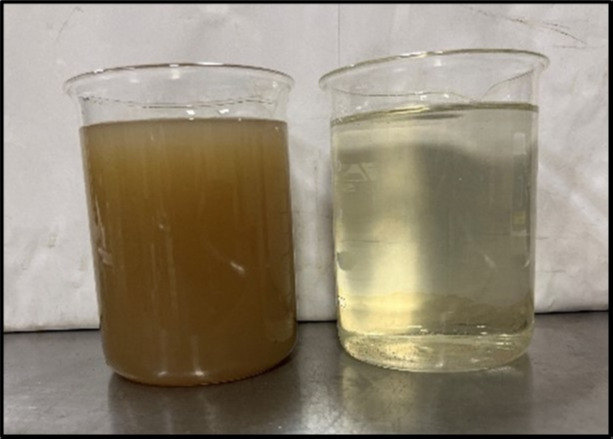

API Separator Effluent Treatment by EPT EOX for Improved DGF Performance

Saskatchewan

Ground Effects successfully treated API separator effluent, exceeding secondary treatment criteria.

Arsenic Removal in Produced and Industrial Waters Using EPT EOX

Saskatchewan, Canada

Ground Effects successfully treated a variety of waste streams including process water, produced water and mine water to below criteria allowing the water to be available for reuse or discharge.

Canola Processing Waste Water Treatment Using EOX

Saskatchewan

Ground Effects successfully treated canola processing waste water using EOX removing TSS, oils/grease and bacteria, reducing BOD to below discharge criteria.

Cyanide and Nitrate/Nitrite Treatment from Mining Waste Water by EPT EOX

Northern Saskatchewan, Canada

Ground Effects successfully treated mining waste water using EOX treatment for high levels of cyanide, nitrate and nitrites.

Dairy Processing Waste Water Treatment by EPT EOX

Southern USA

Ground Effects has successfully treated dairy processing water with high BOD and bacteria allowing the water to be available for reuse or disposal.

ESC 6M Flow Through 24hour

West Texas, USA

With 24 hour continuous flow through the ESC is able to reduce the LGS from 9% to 3% without the use of a centrifuge. This daily snapshot of ESC performance validates the consistant LGS control by ESC on active drilling sites.

Bacterial Elimination in Contaminated Drinking Water in Kenya by Pocket EOX Technology

Kenya

GEE has successfully deployed the Pocket EOX in rural communities in Kenya, eliminating both total and fecal contamination in water, now making the water safe to drink.

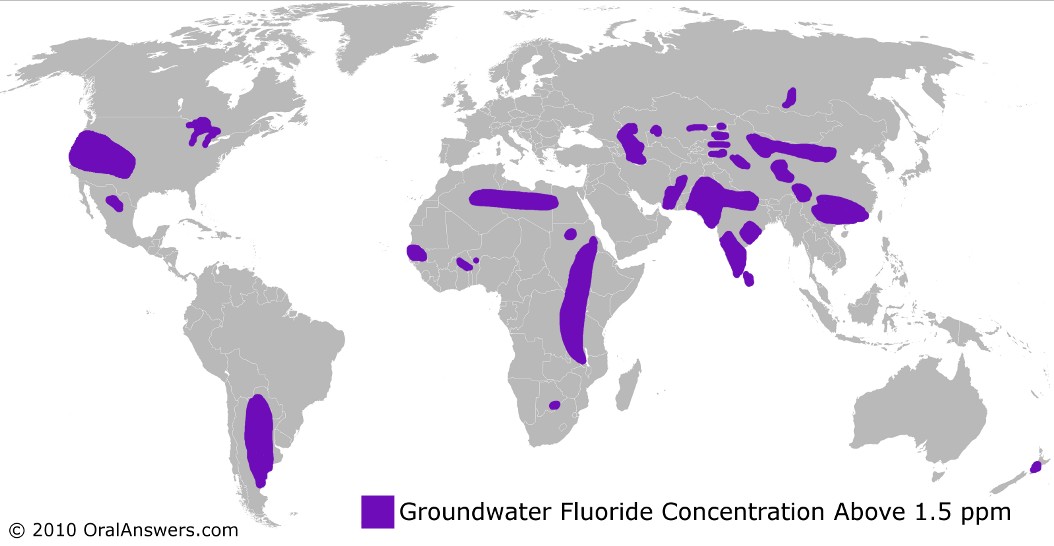

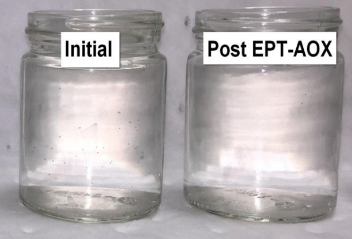

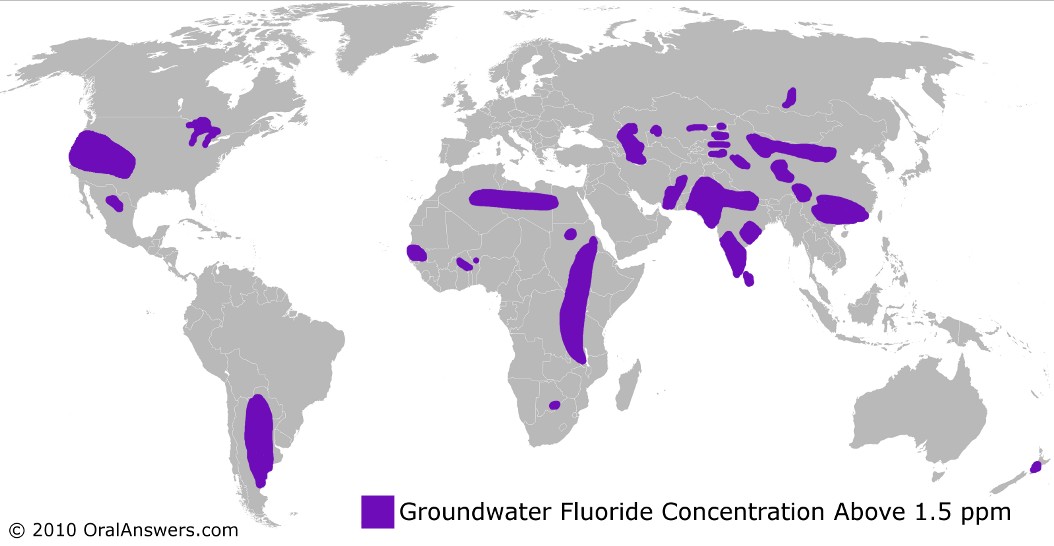

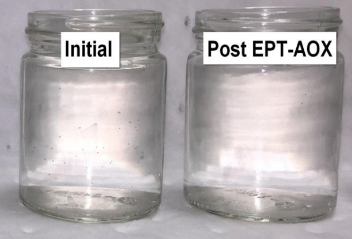

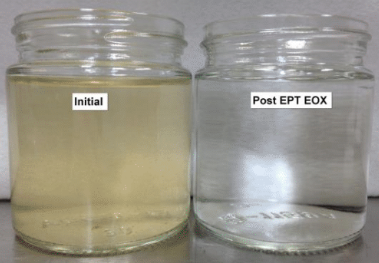

Fluoride Removal in Drinking Water Using the Pocket EOX

Global

Ground Effects has successfully removed high concentrations of naturally occurring fluoride using the Pocket EOX.

Food Production Waste Water Treatment by EPT EOX for Water Reuse

Winnipeg, Manitoba

Ground Effects successfully treated water used in the food production, cleaning, and maintenance using the EPT-EOX technology.

Frac Flowback Water at Waste Treatment Facility

Saskatchewan

Ground Effects successfully treated frac flowback water at a waste treatment facility, increasing the plants ability to reuse and sell the clean water, as well as increase injection rates in disposal wells by up to 87%.

Frac Flowback Water at Waste Treatment Facility

Canada

ElectroPure technology was successful in treating the frac flowback water to well below criteria for all required parameters, and is now made available for reuse.

Complete Destruction of 1.5% H2S in Frac Flowback Water by EPT EOX

Northern British Columbia, Canada

Ground Effects successfully eliminated 15,000ppm concentration of H2S in frac flowback waters on site, eliminating this toxic substance and related safety concerns.

Complete Destruction of H2S in Frac and Produced Waters by EPT EOX Treatment

Northern Alberta, Canada

The EPT EOX treatment resulted in complete destruction of 4% H2S in frac water flowback.

Frac Flowback Water at Drilling Site

Canada

EPT technology was successful in treating the H2S laden produced water to well below criteria for all required parameters.

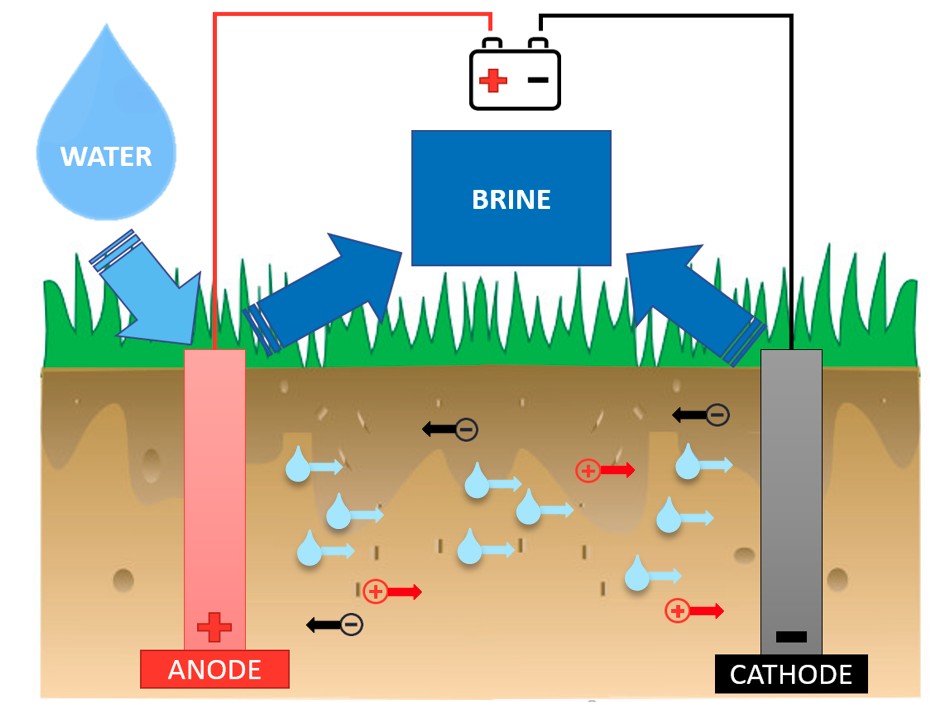

Hexavalent Chromium Treatment by EK3 Technologies for Low Permeable Soils

California, USA

Ground Effects EK3 technology successfully treated and removed hexavalent chromium from low permeable soils to below detection limits over a 12 day period.

Landfill Leachate Treatment with EPT EOX Technology to achieve Discharge Criteria

Louisiana, USA

Ground Effects successfully treated recovered leachate fluid from a landfill operation in Louisiana, USA.

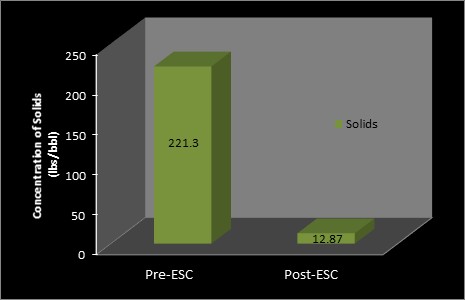

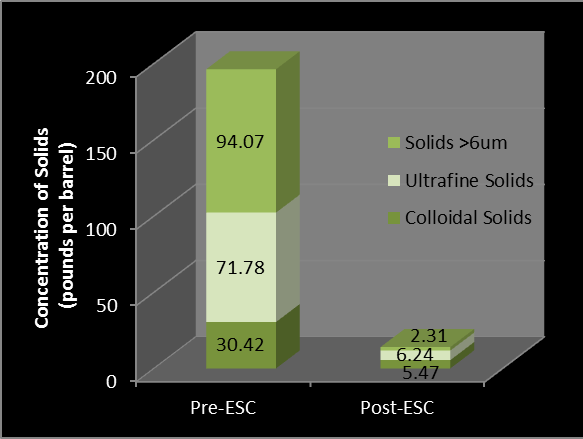

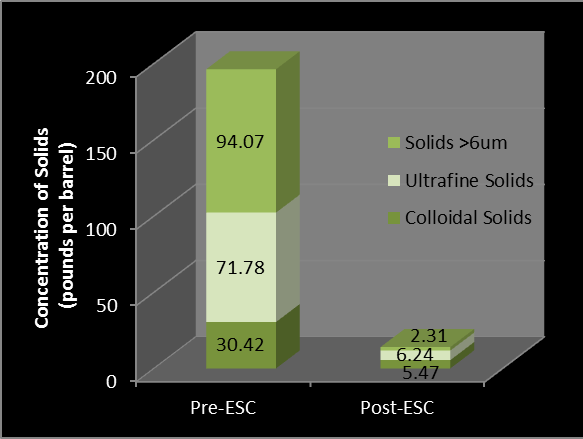

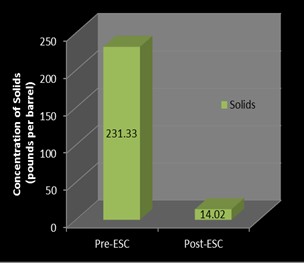

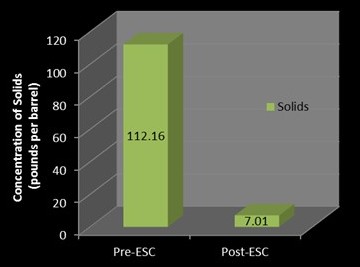

LGS Removal in Invert emulsion Drilling Fluid by ESC Technologies

Texas, USA

Ground Effects successfully removed LGS in three different modes on active drill sites through the continuous removal of LGS over time, minimizing waste volumes and consistently achieving targeting densities.

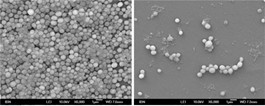

Ultra Fine LGS Particles Removal by ESC, Recovering 65% of the Available Base Oil from the Original Fluid Volume

South Texas Storage Facility

Ground Effects successfully demonstrated the Electro Separation Cell Technology to treat spent fluid from a storage facility in South Texas. Low gravity solids in the feed mud, totalling 20.4%v/v, were reduced to 2.8%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering 82% of the Available Base Oil from the Original Fluid Volume

Gulf of Thailand

Ground Effects successfully demonstrated the Electro Separation Cell Technology to treat spent fluid from drilling operations in the Gulf of Thailand. Low gravity solids in the feed mud, totaling 20%v/v, were reduced to 4.25%v/v. The recovery rate of the base oil was 82% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering on average, 65% of the Available Base Oil from the Original Fluid Volume

Northern British Columbia, Canada

Ground Effects successfully deployed the Electro Separation Cell Technology to treat spent fluid at an active drill site in Northern British Columbia, Canada. Low gravity solids in the feed mud, totaling 21%v/v, were reduced to 2%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering 65% of the Available Base Oil from the Original Fluid Volume

South Texas, USA

Ground Effects successfully deployed the Electro Separation Cell Technology to treat spent fluid from the Eagle Ford formation in Texas. Low gravity solids in the feed mud, totaling 13%v/v, were reduced to 1.5%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Lithium Recovery from Natural Brine Solution by EPT EOX

United States

The EPT EOX treated natural brine waters extracting greater than 90% of valuable Lithium

Ohio Mud Plant Sucessfully Removes LGS Using ESC

Ohio, USA

The ESC successfully manages customers drilling fluid requirements with existing inventory. GEE’s ESC enables mud plant operators to use existing inventory to create a low LGS spec drilling fluid.

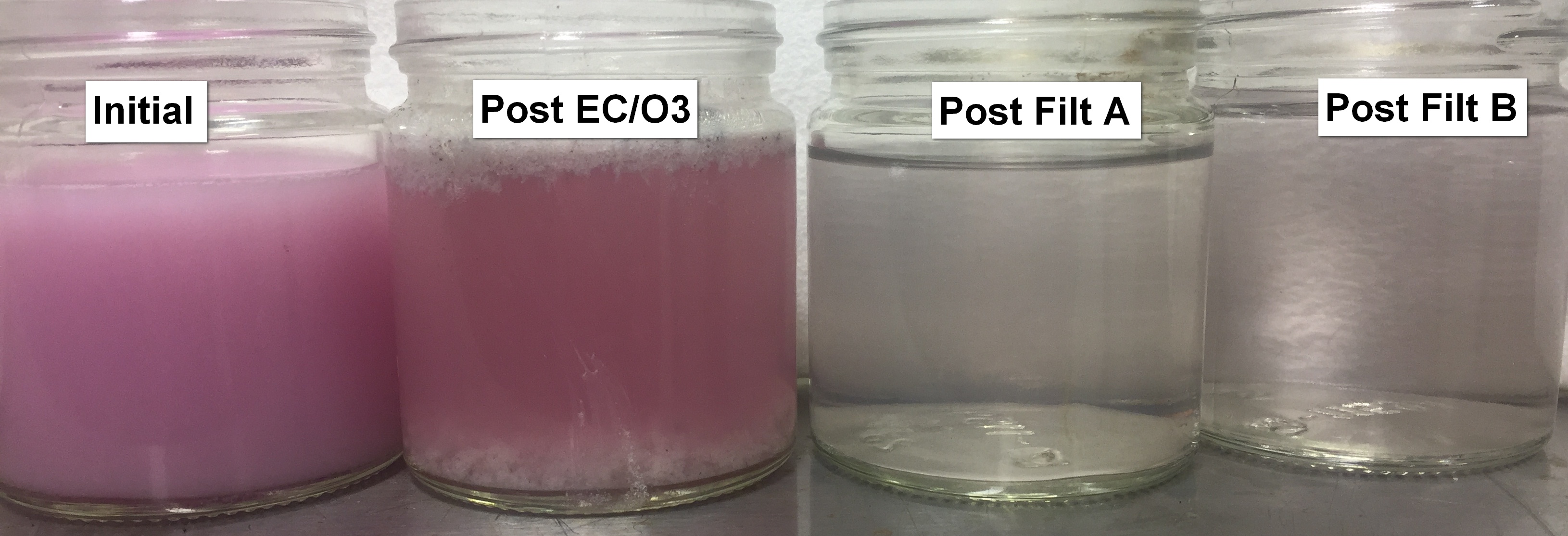

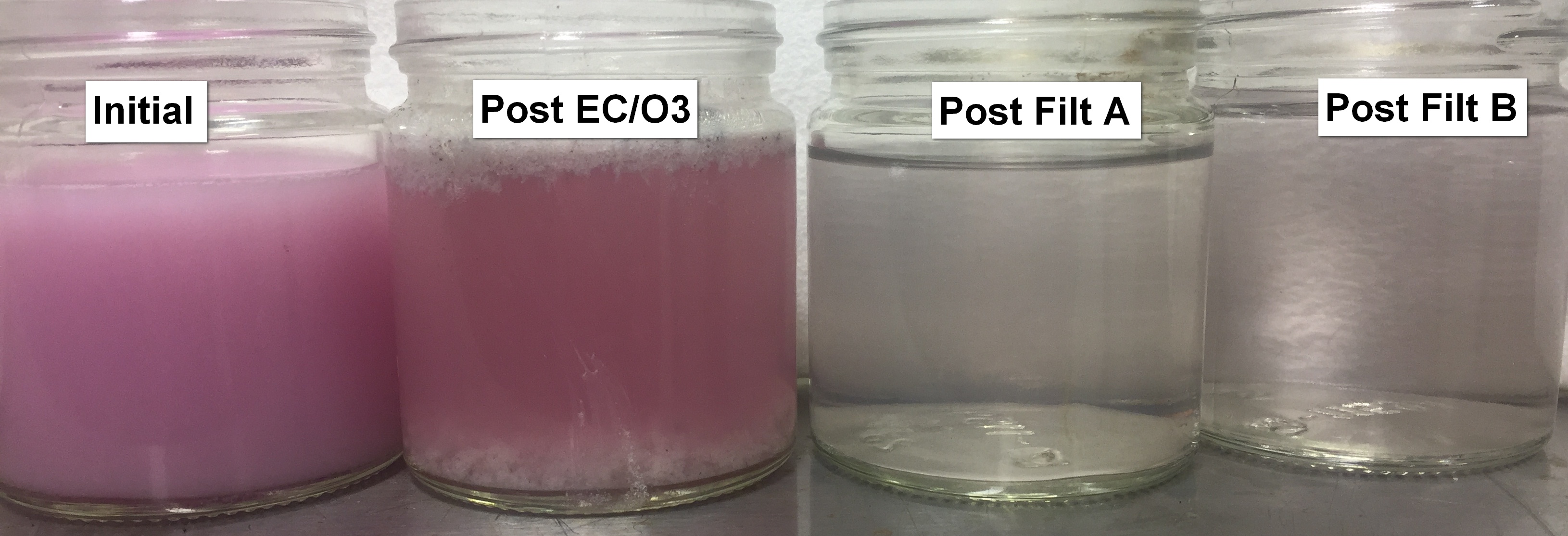

Municipal Waste Water Treatment Plant Using EPT EOX System

Canada

Ground Effects successfully implemented the EPT EOX as a major contributor to the treatment of municipal waste water meeting and exceeding criteria for discharge or irrigation.

Municipal Waste Water Treatment By EPT EOX for Discharge and Reuse

Saskatchewan

Ground Effects successfully treated municipal waste water exceeding discharge and reuse criteria.

NORM Removal from Frac and Produced Waters by EPT EOX Treatment

Texas, United States of America

Ground Effects has successful removed NORMs from frac flowback and produced waters by the EPT EOX treatment.

Oil Water Separation and Recovery in Solution Mining

Southern Saskatchewan, Canada

Ground Effects Oil Water Separation Process was successfull in recovering over $1,000,000 worth of cap oil in one month from ponds associated with Potash Solution Mining.

The EOX Integrated System for Refinery Complex Waste Water for Reuse

Saskatchewan

Ground Effects successfully treated Refinery waste water to below criteria through the use of the EOX Integrated System (EOX-IS).

PFOS and PFOA Treatment in Waste Water Using EPT EOX Technology

United States

Ground Effects successfully treated PFOS/PFOA contaminated Water exceeding discharge and reuse criteria.

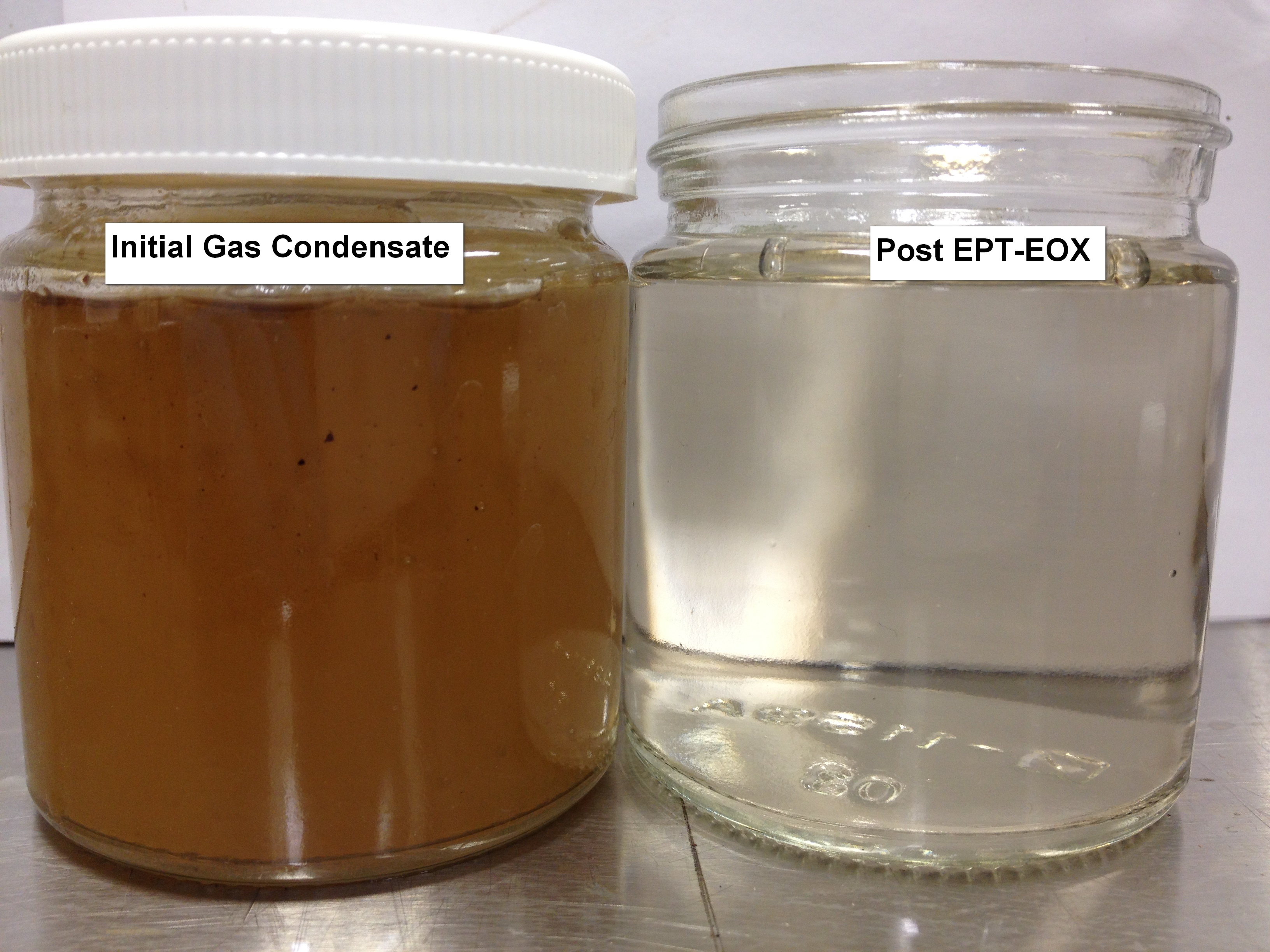

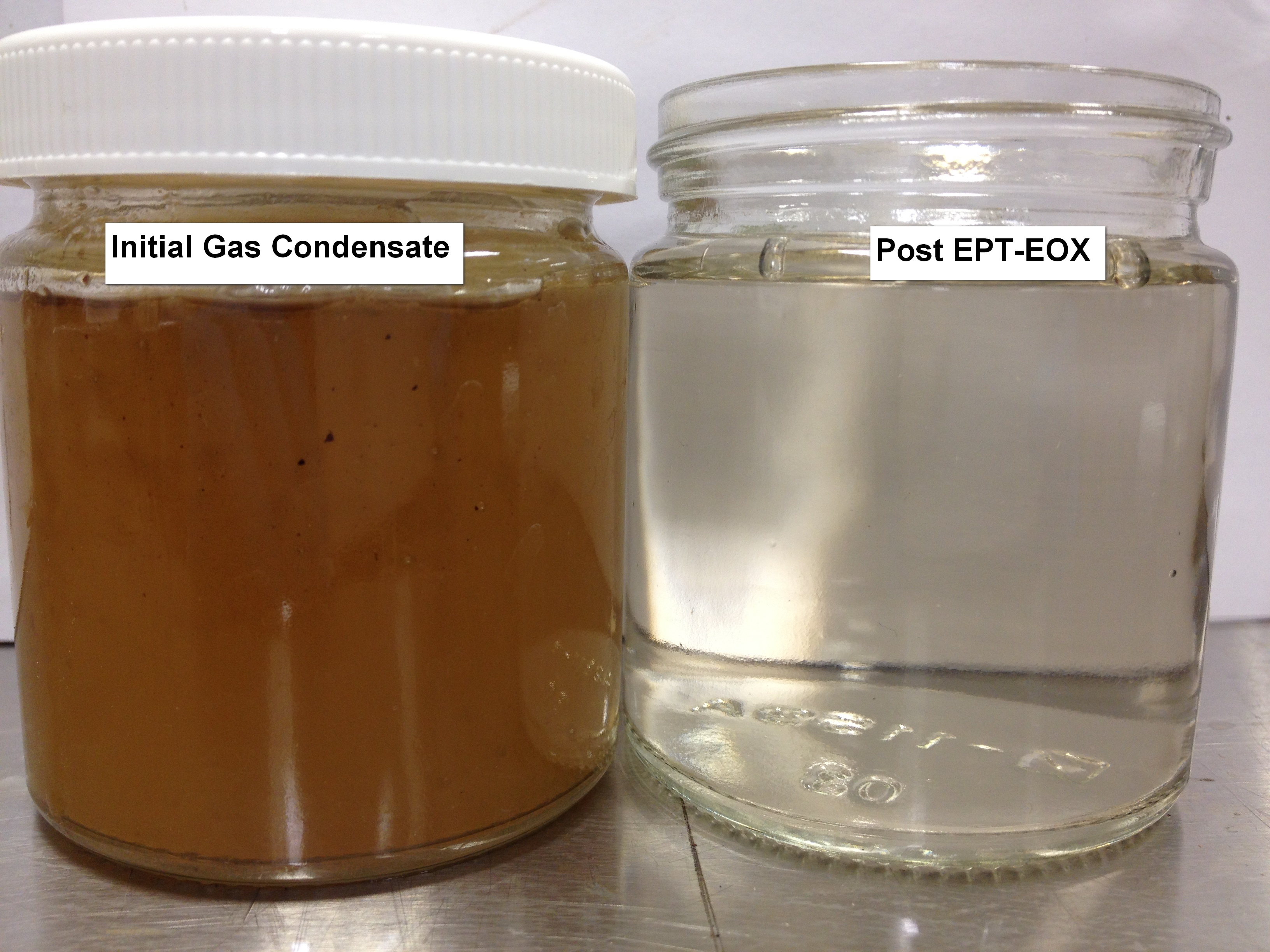

Produced Gas Condensate Treatment by EPT EOX for Reuse as Boiler Feed Water

Canada

Ground Effects has successfully treated produced gas condensate waste water by EPT EOX exceeding criteria necessary for reuse as boiler feed water.

.jpg)

Continued Engineering to Further Optimize EOX in SAGD Processes

Saskatchewan

Ground Effects successfully treated SAGD produced waste water removing silica, TSS, COD, TOC, H2S, metals and bacteria exceeding reuse criteria for steam generation.

Salt Impacted Site Remediation by EK3 Technology

Northern Alberta, Canada

The EK3 technology removed approximately 3.5 metric tonnes of salt within a three month period.

Solids Removal in Corn Ethanol Processing using EPT EOX

USA

Ground Effects removed greater than 90% of remaining solids in process fluid, gaining valuable produced protein as well as allowing the water to be available for reuse in production processes.

Waste Water at a Steel Manufacturing Plant

Canada

ElectroPure technology was successful in treating all waste waters provided including steel production waste water, grey water and raw sewage to well below criteria for reuse.

Sulfolane Concentrate Water Treatment by EPT EOX

Alberta, Canada

Ground Effects successfully treated highly concentrated Sulfolane contaminated water.

Sump Waste Water Treatment by EPT

New Brunswick

The EPT technology was successful in treating all received waste waters to well below criteria for all required parameters for disposal to sewer.

TOC and Ammonia Removal in Ground and Surface Waters by EPT EOX treatment for Municipal Use

Saskatchewan

Ground Effects successfully treated ground and surface waters for many communities in Saskatchewan.

TSS and Nitrate Reduction in Root Vegetable Process Water by EPT-EOX

USA

The EPT EOX system substantially decreased TSS and nitrate concentration in root vegetable process water, thereby allowing more efficient and effective operation of subsequent processes.

The Treatment of Vegetable Wash Water to Remove TSS and Bacteria for Reuse

California

GEE successfully treated vegetable wash water, significantly reducing the need for fresh water, creating a viable solution with ease of treatment and operation in a small footprint and low operating costs.

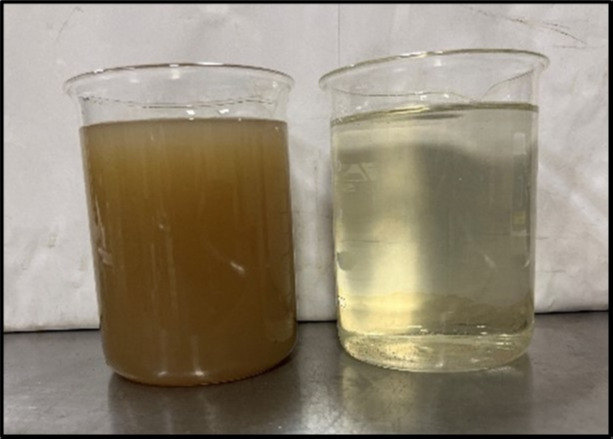

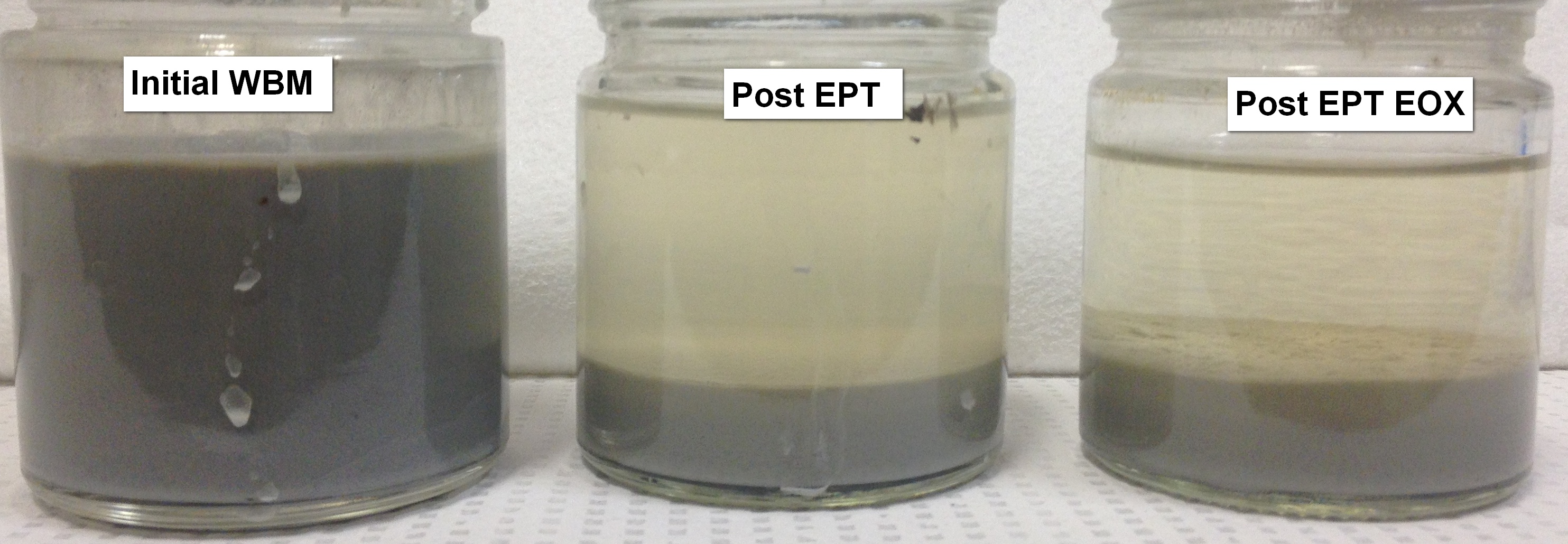

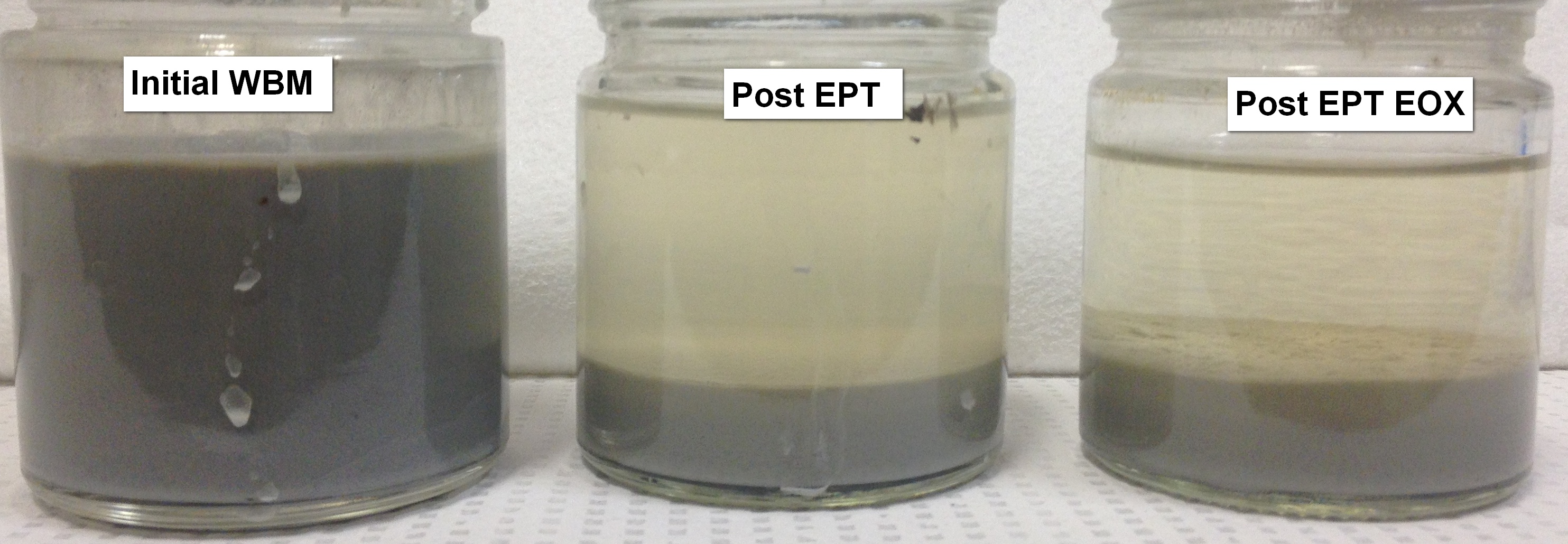

Water Based Drill Mud Treatment EPT EOX for Water Reuse

Canada

Ground Effects has successfully treated water based drill mud using the patented EPT EOX system.

SAGD Waste Water Treatment by EPT EOX for Reuse in Steam Generation

Canada

Ground Effects successfully treated SAGD produced waste water removing silica, TSS, COD, TOC, H2S, metals and bacteria exceeding reuse criteria for steam generation.

High Phosphate Wastewater Treatment By EPT EOX

British Columbia

High phosphate wastewater from municipal plants reduced by 99.6% using EPT EOX Solution

200 BBL Comparison ESC vs Centrifuge

West Texas, USA

Head to Head, equal amounts of fluid-direct comparison. Ground Effects ESC significantly reduces mud weight by removing LGS, while decreasing sludge volumes, reducing waste by half.

API Separator Effluent Treatment by EPT EOX for Improved DGF Performance

Saskatchewan

Ground Effects successfully treated API separator effluent, exceeding secondary treatment criteria.

Arsenic Removal in Produced and Industrial Waters Using EPT EOX

Saskatchewan, Canada

Ground Effects successfully treated a variety of waste streams including process water, produced water and mine water to below criteria allowing the water to be available for reuse or discharge.

Canola Processing Waste Water Treatment Using EOX

Saskatchewan

Ground Effects successfully treated canola processing waste water using EOX removing TSS, oils/grease and bacteria, reducing BOD to below discharge criteria.

Cyanide and Nitrate/Nitrite Treatment from Mining Waste Water by EPT EOX

Northern Saskatchewan, Canada

Ground Effects successfully treated mining waste water using EOX treatment for high levels of cyanide, nitrate and nitrites.

Dairy Processing Waste Water Treatment by EPT EOX

Southern USA

Ground Effects has successfully treated dairy processing water with high BOD and bacteria allowing the water to be available for reuse or disposal.

ESC 6M Flow Through 24hour

West Texas, USA

With 24 hour continuous flow through the ESC is able to reduce the LGS from 9% to 3% without the use of a centrifuge. This daily snapshot of ESC performance validates the consistant LGS control by ESC on active drilling sites.

Bacterial Elimination in Contaminated Drinking Water in Kenya by Pocket EOX Technology

Kenya

GEE has successfully deployed the Pocket EOX in rural communities in Kenya, eliminating both total and fecal contamination in water, now making the water safe to drink.

Fluoride Removal in Drinking Water Using the Pocket EOX

Global

Ground Effects has successfully removed high concentrations of naturally occurring fluoride using the Pocket EOX.

Food Production Waste Water Treatment by EPT EOX for Water Reuse

Winnipeg, Manitoba

Ground Effects successfully treated water used in the food production, cleaning, and maintenance using the EPT-EOX technology.

Frac Flowback Water at Waste Treatment Facility

Saskatchewan

Ground Effects successfully treated frac flowback water at a waste treatment facility, increasing the plants ability to reuse and sell the clean water, as well as increase injection rates in disposal wells by up to 87%.

Frac Flowback Water at Waste Treatment Facility

Canada

ElectroPure technology was successful in treating the frac flowback water to well below criteria for all required parameters, and is now made available for reuse.

Complete Destruction of 1.5% H2S in Frac Flowback Water by EPT EOX

Northern British Columbia, Canada

Ground Effects successfully eliminated 15,000ppm concentration of H2S in frac flowback waters on site, eliminating this toxic substance and related safety concerns.

Complete Destruction of H2S in Frac and Produced Waters by EPT EOX Treatment

Northern Alberta, Canada

The EPT EOX treatment resulted in complete destruction of 4% H2S in frac water flowback.

Frac Flowback Water at Drilling Site

Canada

EPT technology was successful in treating the H2S laden produced water to well below criteria for all required parameters.

Hexavalent Chromium Treatment by EK3 Technologies for Low Permeable Soils

California, USA

Ground Effects EK3 technology successfully treated and removed hexavalent chromium from low permeable soils to below detection limits over a 12 day period.

Landfill Leachate Treatment with EPT EOX Technology to achieve Discharge Criteria

Louisiana, USA

Ground Effects successfully treated recovered leachate fluid from a landfill operation in Louisiana, USA.

LGS Removal in Invert emulsion Drilling Fluid by ESC Technologies

Texas, USA

Ground Effects successfully removed LGS in three different modes on active drill sites through the continuous removal of LGS over time, minimizing waste volumes and consistently achieving targeting densities.

Ultra Fine LGS Particles Removal by ESC, Recovering 65% of the Available Base Oil from the Original Fluid Volume

South Texas Storage Facility

Ground Effects successfully demonstrated the Electro Separation Cell Technology to treat spent fluid from a storage facility in South Texas. Low gravity solids in the feed mud, totalling 20.4%v/v, were reduced to 2.8%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering 82% of the Available Base Oil from the Original Fluid Volume

Gulf of Thailand

Ground Effects successfully demonstrated the Electro Separation Cell Technology to treat spent fluid from drilling operations in the Gulf of Thailand. Low gravity solids in the feed mud, totaling 20%v/v, were reduced to 4.25%v/v. The recovery rate of the base oil was 82% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering on average, 65% of the Available Base Oil from the Original Fluid Volume

Northern British Columbia, Canada

Ground Effects successfully deployed the Electro Separation Cell Technology to treat spent fluid at an active drill site in Northern British Columbia, Canada. Low gravity solids in the feed mud, totaling 21%v/v, were reduced to 2%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Ultra Fine LGS Particle Removal by ESC, Recovering 65% of the Available Base Oil from the Original Fluid Volume

South Texas, USA

Ground Effects successfully deployed the Electro Separation Cell Technology to treat spent fluid from the Eagle Ford formation in Texas. Low gravity solids in the feed mud, totaling 13%v/v, were reduced to 1.5%v/v. The recovery rate of the base oil was 65% of the available oil from the original fluid.

Lithium Recovery from Natural Brine Solution by EPT EOX

United States

The EPT EOX treated natural brine waters extracting greater than 90% of valuable Lithium

Ohio Mud Plant Sucessfully Removes LGS Using ESC

Ohio, USA

The ESC successfully manages customers drilling fluid requirements with existing inventory. GEE’s ESC enables mud plant operators to use existing inventory to create a low LGS spec drilling fluid.

Municipal Waste Water Treatment Plant Using EPT EOX System

Canada

Ground Effects successfully implemented the EPT EOX as a major contributor to the treatment of municipal waste water meeting and exceeding criteria for discharge or irrigation.

Municipal Waste Water Treatment By EPT EOX for Discharge and Reuse

Saskatchewan

Ground Effects successfully treated municipal waste water exceeding discharge and reuse criteria.

NORM Removal from Frac and Produced Waters by EPT EOX Treatment

Texas, United States of America

Ground Effects has successful removed NORMs from frac flowback and produced waters by the EPT EOX treatment.

Oil Water Separation and Recovery in Solution Mining

Southern Saskatchewan, Canada

Ground Effects Oil Water Separation Process was successfull in recovering over $1,000,000 worth of cap oil in one month from ponds associated with Potash Solution Mining.

The EOX Integrated System for Refinery Complex Waste Water for Reuse

Saskatchewan

Ground Effects successfully treated Refinery waste water to below criteria through the use of the EOX Integrated System (EOX-IS).

PFOS and PFOA Treatment in Waste Water Using EPT EOX Technology

United States

Ground Effects successfully treated PFOS/PFOA contaminated Water exceeding discharge and reuse criteria.

Produced Gas Condensate Treatment by EPT EOX for Reuse as Boiler Feed Water

Canada

Ground Effects has successfully treated produced gas condensate waste water by EPT EOX exceeding criteria necessary for reuse as boiler feed water.

.jpg)

Continued Engineering to Further Optimize EOX in SAGD Processes

Saskatchewan

Ground Effects successfully treated SAGD produced waste water removing silica, TSS, COD, TOC, H2S, metals and bacteria exceeding reuse criteria for steam generation.

Salt Impacted Site Remediation by EK3 Technology

Northern Alberta, Canada

The EK3 technology removed approximately 3.5 metric tonnes of salt within a three month period.

Solids Removal in Corn Ethanol Processing using EPT EOX

USA

Ground Effects removed greater than 90% of remaining solids in process fluid, gaining valuable produced protein as well as allowing the water to be available for reuse in production processes.

Waste Water at a Steel Manufacturing Plant

Canada

ElectroPure technology was successful in treating all waste waters provided including steel production waste water, grey water and raw sewage to well below criteria for reuse.

Sulfolane Concentrate Water Treatment by EPT EOX

Alberta, Canada

Ground Effects successfully treated highly concentrated Sulfolane contaminated water.

Sump Waste Water Treatment by EPT

New Brunswick

The EPT technology was successful in treating all received waste waters to well below criteria for all required parameters for disposal to sewer.

TOC and Ammonia Removal in Ground and Surface Waters by EPT EOX treatment for Municipal Use

Saskatchewan

Ground Effects successfully treated ground and surface waters for many communities in Saskatchewan.

TSS and Nitrate Reduction in Root Vegetable Process Water by EPT-EOX

USA

The EPT EOX system substantially decreased TSS and nitrate concentration in root vegetable process water, thereby allowing more efficient and effective operation of subsequent processes.

The Treatment of Vegetable Wash Water to Remove TSS and Bacteria for Reuse

California

GEE successfully treated vegetable wash water, significantly reducing the need for fresh water, creating a viable solution with ease of treatment and operation in a small footprint and low operating costs.

Water Based Drill Mud Treatment EPT EOX for Water Reuse

Canada

Ground Effects has successfully treated water based drill mud using the patented EPT EOX system.